Stavari: Additive Manufacturing Processes For Complex Products With A Wide Range Of Variants In A Highly Functional Structural Steel Design

The increasing variant intensity in small series, the reduction in the time-to-market in development, and the demand for material efficiency are opportunities for metal 3D printing in the automotive industry. This is why the EDAG Group, the world’s largest independent engineering service provider for the automotive industry, and nine leading partners are carrying out research into a fully integrated process chain for the additive manufacture of complex components using an innovative steel grade.

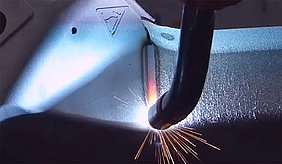

Image via EDAG

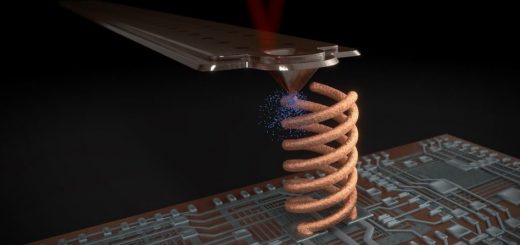

Image via EDAG

In the current StaVari research project, a steel alloy tailor-made for car body applications was first of all defined. A new powder alloy has been developed which, in the laser-additively processed state, has properties comparable to those of the classic DP800 dual-phase steel, and could also significantly reduce costs (approx. 60 percent is envisaged) compared to conventional alloys.

Together with its partners, the EDAG Group specified requirements, developed concepts for component design, developed material parameters, material maps and CAE design methods, and demonstrated the powder alloy defined and implemented in the overall project in typical body components. Powder production, the additive manufacturing process, thermal treatment and post-processing were developed for use in the laboratory, and then scaled up to industrial proportions. New strategies were also developed for joining laser-additively produced components. As a result, intelligently cooperating robots are able to efficiently join laser-additively manufactured steel components in a camera-controlled MAG welding process in which little tooling is used and tolerances are balanced out.

As a demonstrator, the EDAG Group engineers designed a heavy-duty, variant-intensive vehicle structure, which has now been manufactured in close cooperation with all project partners. There are plans to test the demonstrator in a real test as the project progresses. The demonstrator consists of an LAM-manufactured B-pillar foot reinforcement and a load path-compatible C-pillar node. The bionic structure and the load level-specific functions open

up new approaches.

StaVari opens up new perspectives for the automotive industry to shorten the time-to-market for prototypes and small series for steel-based bodies in small and medium quantities; for example passenger cars with alternative drives, commercial vehicles, two-wheelers, construction machinery or rail vehicles.

Under the auspices of the EDAG Group, the partners Ziehm Imaging, Salzgitter Mannesmann Forschung, Cloos, Concept Laser, hema electronic, Indutherm, IWT Bremen, Fraunhofer IAPT and SLK TU Chemnitz are all working on the project, which will be funded by the Federal Ministry of Education and Research (BMBF) until April 2020.

This research project is funded by the German Federal Ministry of Education and Research (BMBF) under the number 02P15B050, and supervised by the Project Management Agency Karlsruhe (PTKA).

Source: EDAG

Recent Comments