Metro Aerospace: Using 3-D Printing To Make Gas-Guzzling Cargo Airplanes Fly Better

One of the advantages of 3-D printing is that it makes it possible to manufacture things that wouldn’t make sense or even be possible with legacy technologies. Metro Aerospace provides an excellent example of this. Since its inception almost three years ago, Leslie Peters, the company’s President and CEO, has entered a market with a customer base spanning almost 70 countries.

Image Courtesy Metro Aerospace

Image Courtesy Metro Aerospace

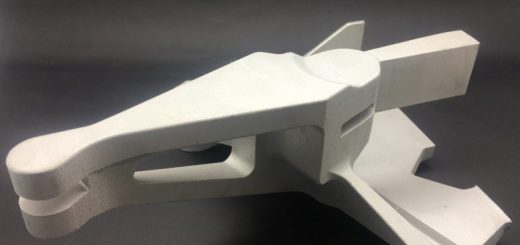

Metro makes microvanes, engineered shapes that are mounted on aircraft fuselages. They redirect airflow to break up eddies, countercurrents that would normally increase drag. The microvanes create vortices to disrupt those countercurrents. Adding them reduces fuel usage, reduces carbon emissions, increases range, and enhances the performance of the aircraft while extending its service life.

Microvanes installed on an aircraft cargo door. Image Courtesy Metro Aerospace

Microvanes installed on an aircraft cargo door. Image Courtesy Metro Aerospace

Microvanes have been around for a while, but have only recently gotten past the prototyping stage. “It all started with Catalyze Dallas,” said Peters. “They’re a venture development firm that takes intellectual property from America’s largest defense firms to commercial markets.” The firm approached Peters, who had experience in parts manufacturing for aerospace and other precision applications, and who’d also previously worked with metal additive manufacturing (AM). “We started Metro specifically to introduce microvanes,” Peters said.

She subsequently met with Lockheed-Martin, who had tested microvanes for 18,000 flight hours over ten years, to discuss several potential applications. They decided to focus initially on the C-130H Hercules and C-130J Super Hercules cargo airplanes for the microvane application. Testing for those aircraft had been completed not just for the right airflow, but also to develop the method for adhering the parts to the fuselage without riveting, to ensure no interference with air drops or paratroopers, and to make certain there would be no damage to the aircraft in the event a microvane came loose.

“We started Metro in September 2016, and completed our first article product in February 2017,” said Peters. The tight timeline and other factors were a big challenge. “I had background in metal AM, but I had to learn nylon and polymers and entirely new equipment.” Those realities drove the decision by Peters to partner with 3D Systems On Demand services for manufacturing the microvanes. “I tapped their technical expertise related to both the material and AM processing, as well as leveraging their machine capacity to quickly come on-line,” Peters said.

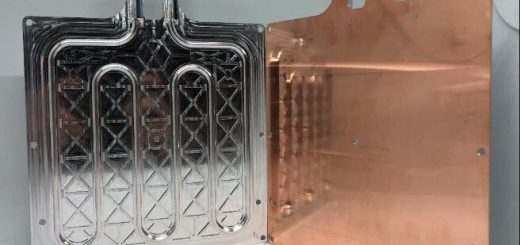

Each set of microvanes is 20 unique parts, which are adhered to the fuselage on either side of the large rear door of the cargo aircraft. The parts require use of virgin polymers, which in turn requires dedicated printers. The microvanes are printed using 3D Systems’ Selective Laser Sintering (SLS) technology. The front end of the manufacturing process is standard, but unfortunately the parts do require additional special steps. “Although we can conduct rapid manufacturing, the post-processing for the finishing is manual and labor intense, an area we are looking to further streamline,” Peters said. “Also, testing, packaging and other shipment requirements are well defined for traditionally manufactured parts, but for our parts being 3-D printed we had to be a bit creative to meet the stringent requirements in order to not add excess time to our overall production schedule.”

Post-production microvane cleaning. Image Courtesy 3D systems

Post-production microvane cleaning. Image Courtesy 3D systems

Understandably, quality is a central focus in the aerospace industry. Metro has achieved AS9100D certification, a company-level credential based on a standard written by the Society of Automotive Engineers (SAE) specific to quality systems for aerospace firms doing design, production, and servicing.

Manufacturing on a relatively new platform has its challenges. “Timeframes are compressed in the AM world but 3-D printing is not as easy as people tend to believe,” Peters said. “You can’t just buy a printer and start making production parts. There’s a lot to learn and manage – processes, suppliers, materials… Also, the front end of the supply chain hasn’t been developed yet. In mature industries, you have standards and specifications that make it easier to work collaboratively and quickly with suppliers. We’re not quite there yet for AM. In our case, both 3D Systems and Lockheed’s Skunkworks engineering experts worked with us throughout the initial manufacturing process to ensure we adhered to the traditional standards in regards to part qualification and certification, while adding new standards that more closely fit for AM.”

Still, Peters sees huge opportunities ahead. “Although to-date several foreign militaries have purchased microvanes for their Hercules fleet, the U.S. Armed Forces has the most to gain. With microvanes providing a fuel reduction of 25-30 gallons per hour, the annual fuel reduction alone amounts to millions of dollars saved for the U.S. fleet, and this doesn’t take into account the reduced engine wear and tear,” she said. And more military applications abound. Testing of microvanes for the C-17 Globemaster transport plane has been completed. Next up is a look at the KC-135 Stratotanker refueling aircraft, with perhaps the C-5 Galaxy transport to follow.

Commercial applications could be on the horizon as well. “We just got certified on the L-100, the civilian version of the C-130H, with our partner Lynden Air Cargo receiving the FAA STC this past October, which was a huge hurdle. This lays the groundwork for us to begin looking at how microvane technology applies to Boeing and Airbus commercial planes, particularly cargo aircraft,” Peters said.

Eventually Metro will look at bringing their printing in-house, as they develop their own expertise with the technologies and materials. And they plan to stay in the U.S. with a continued footprint in the Dallas, Texas area.

Peters sees the mix of challenges and opportunities in their 3-D printing manufacturing platform as a plus. “It’s really fun – we learn something new every day,” she said. “The big challenge continues to be lack of industry expertise – we’re shorthanded! What we’re doing is leading-edge.”

But she also sees 3-D printing advancing rapidly. “It’s actually not new – AM has been around since the Reagan era,” she said. “But we’re just now really moving from prototype to high volume production parts. Clearly it’s no longer a novelty for aerospace.”

Source: forbes

Recent Comments