Renishaw Extends Paramatters Collaboration

Renishaw is working with autonomous topology optimisation company Paramatters to give manufacturers access to efficiently manufactured metal 3D printed parts.

The galvanometer block additively manufactured using four lasers on the RenAM 500Q over a period of 19 hours The galvo block additively manufactured using four lasers on the RenAM 500Q over a period of 19 hours.

( Source: Renishaw )

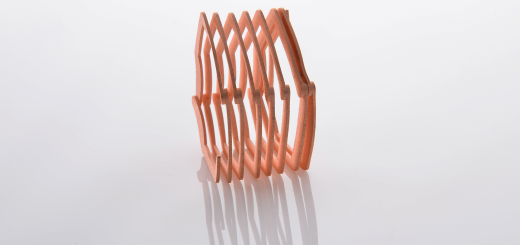

Paramatters’ CogniCAD cloud solution enables users to easily upload part geometries for optimisation and automatically produces lightweight macro, meso and lattice structures using generative design principles backed up with high resolution finite element analysis (FEA) validation. CogniCAD users are no longer constrained by traditional complex CAD/CAE/CAM tools, instead they simply upload their part and follow the intuitive CogniCAD workflow and user-friendly interface to prepare a printable model.

![]() Increasing Relevance of Lightweight Design

Increasing Relevance of Lightweight Design

Renishaw has previously used CogniCAD to reduce the weight of the upper mounting bracket for Ecosse Moto Works’ motorcycle, the Nightstalker. Lightweight components are important in motorcycles for ensuring fuel efficiency and improved dynamics. Here, the two complementary technologies are used together to produce lightweight and structurally robust components and Renishaw’s collaboration with Paramatters has made both technologies accessible to its customers.

“We worked with Renishaw to establish a smooth workflow that made it possible to automate the entire process from design to manufacturing,” explained Michael Bogomolny, Co-Founder and CTO of Paramatters. “CogniCAD uses topology optimisation, computational geometry and high-performance computing to autonomously generate designs that are adapted to make the best use of AM.”

In a new extension of the collaboration, Renishaw will use CogniCAD at its AM Solutions Center in West Dundee, Chicago. Paramatters will join Renishaw’s network of software vendors and will provide a “Click to Print” functionality from CogniCAD. This will enable design review and printability assessment by Renishaw experts before additive manufacture commences. Paramatters will also have access to Renishaw additive manufacturing (AM) systems for joint customer projects.

![]() Generative Design in Lightweight Parts

Generative Design in Lightweight Parts

“Generative design has a clear role to play in lightweighting parts that cannot be produced by computer numerical control (CNC) machining alone,” explained Stephen Anderson, AM Business Development Manager at Renishaw Inc. “However, for many manufacturers, the initial investment required to perform such optimisations is too high. By working with Paramatters potential users can easily try topology optimisation, see the results and then engage with Renishaw to assess final suitability for additive manufacturing.”

![]() Renishaw

Renishaw

5-Axis Scanner Delivers Faster Measurement Results

“We successfully use Renishaw to additively manufacture Paramatters optimised designs and have been really impressed with the results,” commented Bogomolny. “We have developed CogniCAD, Meta-Materials Compiler and our new Unique Meso-Structural Designer, that can be used to develop realistic bone-like structural implants – all with simple web-based GUIs allowing for the fast creation of optimal, FEA checked, components. We believe working with Renishaw and implementing “Click to Print” in our offering will help open up ever wider markets for metal additive manufacturing and our software.”

Source: SPOTLIGHTMETAL

Recent Comments