Siemens Implements An Additive Manufacturing Process Simulation Solution To Transform 3D Printing

Global technology giant Siemens has announced its plans to implement new Additive Manufacturing (AM) Process Simulation solution to predict distortion during the 3D printing process. The product is fully integrated into Siemens’ end-to-end Additive Manufacturing solution, which works to assist manufacturers in designing and printing useful parts at scale.

Image Source: Siemens

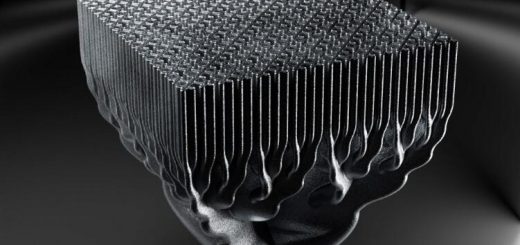

Image Source: Siemens

“Using the Simcenter 3D AM Process Simulation solution at toolcraft will allow us to complete our additive manufacturing workflow,” explained Christoph Hauck, Managing Director, MBFZ toolcraft GmbH.

“Through real-world testing, we have gained confidence that the Siemens AM Process Simulation solution will assist us in ensuring quality output from our print process.”

When metal parts are 3D printed, the method used to fuse the layers of the print typically involves heat. As the layers build up, the residual heat can cause parts to warp, causing structural issues within the part itself to print stoppage. Simulation of the printing process will therefore seek to resolve or alleviate many of these problems.

The new process simulation product will be integrated into the Powder Bed Fusion Process chain in the Siemens PLM Software Additive Manufacturing portfolio and is used to predict distortion for metal printing. The product provides a guided workflow to the user that allows for the assessment of distortions, the prediction of recoater collisions, prediction of areas of overheating, and other important feedback about the print process. With over 140,000 customers worldwide, Siemens PLM Software works with companies of all sizes to transform the way products and assets in operation are used and understood.

Through the AM Process Simulation solution, users are provided the ability to iterate on a solution between the design and build tray setup steps of the workflow, and the simulation step. This closed feedback loop is possible due to the tightly integrated nature of the Siemens digital innovation platform. The simulation data created feeds into the digital thread of information which informs each step of the printing process. This digital backbone enables the system to develop pre-compensated models and, more importantly, to feed those seamlessly back into the model design and manufacturing processes without additional data translation.

“This solution is the latest addition to our integrated additive manufacturing platform, which is helping customers industrialise additive manufacturing by designing and printing useful parts at scale,” commented Jan Leuridan, Senior Vice President for Simulation and Test Solutions at Siemens PLM Software.

“By using a combination of empirical and computational methods we can increase the accuracy of the simulation process, feeding the digital twin and helping customers better predict their real-world print results. We have proven this over months of real-world testing with some selected first adopter companies. Providing corrected geometry and closed loop feedback can ultimately allow our customers to get better results from their additive manufacturing processes, helping to achieve that first-time-right print and realize innovation with this technology.”

The AM Process Simulation solution is expected to be available in January 2019, as part of the latest NX software and Simcenter 3D software. For more information about producing quality parts with industrial additive manufacturing software.

Source: Manufacturing Global

Recent Comments