INTAMSYS Releases the Multi-material 3D Printing Integrated Solution at FOMNEXT 2018

INTAMSYS, a Shanghai based high performance functional materials industrial additive manufacturing manufacturer, is continuously devoted to develop innovative 3D printing solutions. INTAMSYS is famous for its FUNMAT series 3D printers, which are able to print PEEK and other high performance functional materials. During the 2018 Formnext show, INTAMSYS added a new product, the FUNMAT PRO 410, to its FUNMAT series product line.

“Since we launched our first high performance functional materials 3D printer FUNMAT HT two years ago in Formnext, a lot of customers have been attracted by its excellent multiple functional materials 3D printing capabilities and its affordable price. This desktop functional material 3D printer has empowered customer more possibilities to explore more functional material and more potential applications. As more and more customers knew the potential behind FUNMAT HT, they requested us with higher requirements, such as a bigger print size, easier to use, higher printing speed etc.. FUNMAT PRO 410 is the right answer to our customer requirements.” Said Charles Han, CEO from INTAMSYS.

The FUNMAT PRO 410 provides an excellent multiple functional materials all-in-one solution for industrial additive manufacturing. It can be used for functional parts 3D printing and low volume production. It is an office friendly machine and can also be used in factory.

The 3d printer enjoys a big size, up to 12x12x16 inches. The printer also includes an advanced thermal design. The nozzle temperature is 450℃. The chamber temperature goes up to 90℃ and the build plate goes up to 160℃. This high temperature feature makes this printer able to print more than 20 type of functional materials.

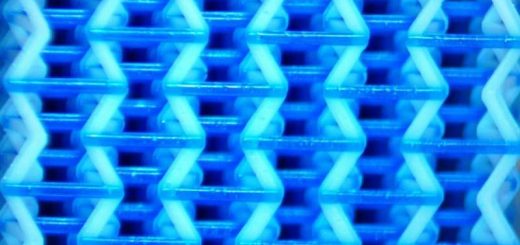

Furthermore, this printer provides a smart dual nozzle printing solution. The support material nozzle can be adjusted up and down when printing. This can avoid model scratching problem in normal dual nozzle design. In addition to this, INTAMSYS provides a total support solution for each thermo plastic. SP1000 for PLA, SP2000 for engineering plastic like PA, PC+CF, PC ABS etc., and SP5000 for high performance functional material like PEEK, PEKK, PEEK+CF, PEI, PPSU etc.. All these support materials are soluble or breakaway. Customers can achieve smooth support surface.

The printer also features a heated filament chamber in order to avoid filament moisture absorption during printing process.

A lot of other features make this printer smarter and easier to use. Those features include Automatic leveling, Jam warning, filament absence warning, and power failure recovery. All these feature make this printer very suitable for continuous production.

The FUNMAT PRO 410 also enjoys network connection capability, including wifi and internet, suitable for mass 3D printer production management.

“INTAMSYS solutions bring us strong tools to deal with jigs and fixtures application in our production line because of their FUNMAT series printer’s strong multiple functional materials capabilities. In our production line, we need different types of jigs & fixtures with different types of materials, from ABS, Nylon, Carbon Fiber to PEEK, etc.. INTAMSYS 3D printer can provide a multiple functional materials 3D printing all-in-one solution to us.” said Roger, business development director from BYD.

During the Formnext show, the other INTAMSYS 3D printers displayed, including the upgraded FUNMAT HT, the FUNMAT PRO and the FUNMAT PRO HT, also received a lot of attention and interest. Indeed, 3 new features have been aaded to the FUNMAT HT : automatic leveling, improved high performance motor drivers, as well as a new ceramic glass build plate.

Source: INTAMSYS

Recent Comments