Bike Saddle Reimagined

Along with handlebars and pedals, the saddle is one of only three components connecting the rider with the bike. Therefore, the importance of the saddle cannot be underestimated.

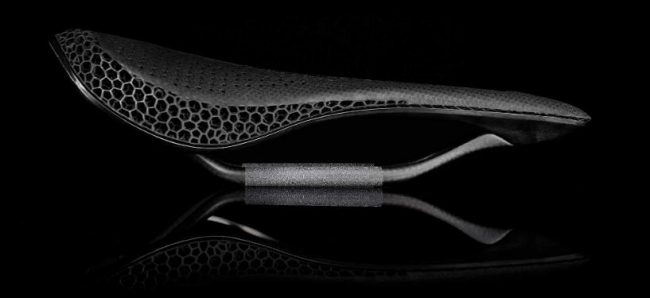

“To create the most comfortable performance saddle” – nothing less has been the target when American bicycle manufacturer Specialized teamed up with 3D-printing pioneer Carbon and polymer solutions provider OECHSLER to develop a brand-new, additively manufactured bike saddle. Together the three partners created a breakthrough in rider comfort at the speed of light in terms of production. Over the course of the last 25 years, Specialized has invested heavily in research and innovation, with the goal of improving riders’ experience on the bike. This has all been made possible by Specialized’s Body Geometry methodology: Identify a problem, solve it with design, validate with science. However, the possibilities of conventional production techniques and materials (especially foam) were exhausted at a certain point—particularly in terms of comfort and rider stability. At this turning point, Specialized started exploring the benefits of free design, rapid product development, and serial production in additive manufacturing. Thanks to Carbon’s innovative 3D-printing technology, the S-Works Power with Mirror technology was the first successful saddle expanding product features beyond what was previously possible. It went straight on to become an award-winning product, impressively demonstrating the capabilities of Carbon Digital Light Synthesis™ (Carbon DLS™) technology. With the vision to push limits even further, Specialized has just introduced the brand-new successor S-Works Romin Evo with Mirror technology. This product innovation resulting from the close collaboration between Specialized, Carbon, and OECHSLER stands for a unique riding experience for cyclists. It has also been a proof point in showing that the 3D-printing technology provided by Carbon is highly scalable and thus has paved the way for OECHSLER to become production partner of choice for Carbon. This resulted in a direct and agile client relationship with OECHSLER taking over responsibility for working with Specialized as they the develop future products.

![]() How it all started

How it all started

Back in 2016, OECHSLER partnered with Carbon for the first time, driven by a large customer project.

“We were introduced to each other by a global sporting goods OEM and decided to collaborate on scaling 3D printing for a high-volume project,”

Markus Bischoff, Vice President Sales for Additive Manufacturing and Sporting Goods at OECHSLER.

Around the same time, Specialized acquired its first Carbon M1 printer, for prototyping and testing purposes. “Additive manufacturing allows for a more efficient development time including countless incremental improvements until the final product. The speed at which we were able to bring a design from the computer to a prototype on a bike for our ride testers to give feedback is game-changing,” says Emma Boutcher, Product Manager at Specialized.

Since 2016, Specialized and OECHSLER have gained deep expertise in Carbon’s DLS™ Technology. While Specialized, for example, reduced the overall development process for a saddle from the typical 18–23 months’ timeline to just 13 months, OECHSLER built one of the largest polymer-based additive manufacturing fleets, with over 150 3D printers globally, producing well over one million additively manufactured components per year since 2019. “At OECHSLER we focus on bringing additive manufacturing to industry scale and enable series production processes,” Bischoff says.

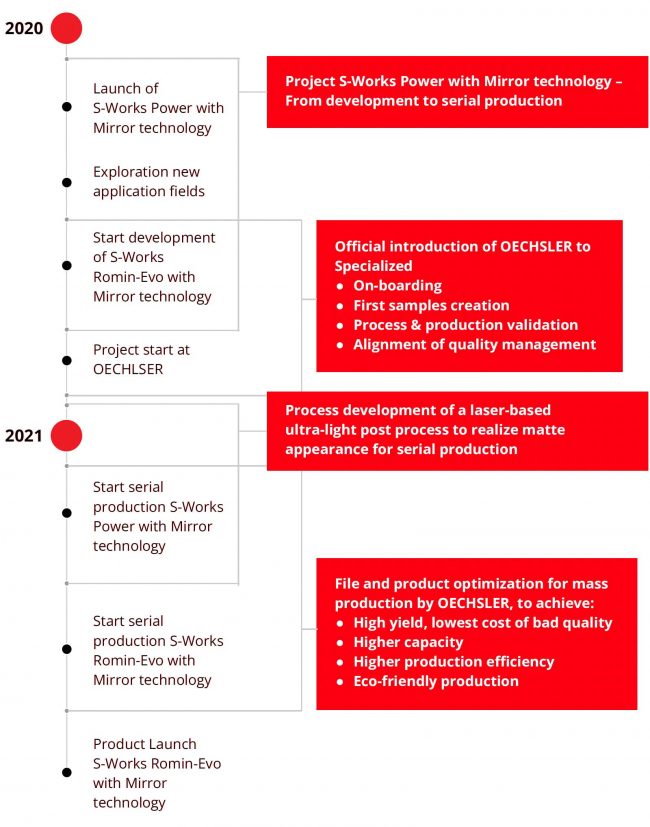

When Carbon, Specialized, and OECHSLER came together in the second half of 2020, the challenges facing the companies were great. Within four months, prototyping of the S-Works Romin Evo with Mirror technology was completed, and within another two months, serial production was industrialized to ensure product launch just ten months after OECHSLER’s onboarding.

![]() Timeline of events

Timeline of events

![]() S-Works Romin Evo with Mirror Technology – Product and Production Process

S-Works Romin Evo with Mirror Technology – Product and Production Process

The development process started by analyzing feedback from ride testers collecting data from pressure tests, and using findings from previous development processes. Carbon and OECHSLER engineers translated these into technical specifications.

Since the development phase was very time-constrained, the benefits of Carbon’s DLS™ Technology were critical and accelerated the process in a breakthrough way. The short iteration loops allowed the collection of large amounts of data. A total of 14 different designs have been developed and tested. A typical iteration loop, which consisted of testing, collecting, and analyzing data to turn the insights into product adjustments, took an average of 21 days.

Kelley McCarroll-Gilbert, Business Development Director at Carbon, remarks about the project: “It was fantastic to see the OECHSLER, Specialized, and Carbon teams work together to rapidly design, print, test, and repeat to develop a ground-breaking new saddle that takes full advantage of all the benefits that can only be recognized by using additive manufacturing at scale.” Based on the final prototype, OECHSLER engineers optimized the print file for serial manufacturing to increase yield, speed production, and reduce environmental impact without compromising performance and design.

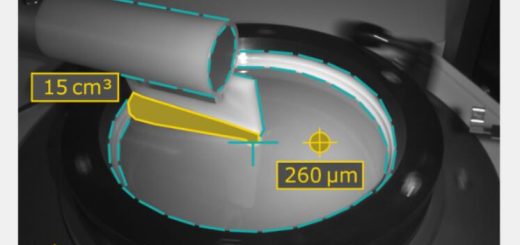

OECHSLER’s highly flexible Carbon DLS production had already demonstrated manufacturing capabilities in printing various applications (e.g., shoe soles, football helmet inlays) in the past. However, to realize the matte appearance, it was necessary to develop and validate a laser-based ultra-light post-process. From the first trial to series production, OECHSLER’s process specialists developed this post-process in record-breaking four months.

The result: The project took six months from prototype to industrialization.

The S-Works Romin Evo with Mirror technology on a bike

The S-Works Romin Evo with Mirror technology on a bike

Introducing S-works Romin Evo with Mirror technology

The S-Works Romin Evo with Mirror technology has been specially developed for the performance cycling market. These applications must meet the highest level in rider perceived comfort, pelvic stability, and soft tissue health. Poor seat comfort can lead to injuries and abrasions, and thus directly affects the performance of the cyclist.

Specialized, Carbon, and OECHSLER have joined forces to create a new riding experience for the end-user. The damping and energy recovery characteristics of the lattice structure are programmable via the geometry of the lattice, the thickness of the 22,000 lattice bars, and the cell size of the lattice. This allows different areas of the S-Works Romin Evo with Mirror technology to have different damping characteristics, leading to superior comfort. Overall, the seating pressure is being reduced by 18 to 26 percent compared to foam.

The 190-g S-Works Romin Evo with Mirror Technology is 260 mm long with a width of 143 or 155 milimeters.

Pressure Map comparing the S-Works Romin Evo with Mirror technology to a traditional foam saddle

Pressure Map comparing the S-Works Romin Evo with Mirror technology to a traditional foam saddle

![]() A glance into the future

A glance into the future

Carbon’s technology platform of printer hardware, software, and materials enables the print quality and speed necessary for high-volume production, and provides materials with characteristics required for a great product.

“From the beginning, Specialized had a clear eye for innovation and bringing new, high performing parts to market. We are excited to continue working closely with both the Specialized team and OECHSLER team to continue bringing new Carbon DLS™ products to the cycling market.”

Kelley McCarroll-Gilbert, Business Development Director at Carbon

Specialized strives to create a rider benefit in all aspects of their product offerings. In doing so, they continuously break the boundaries of traditional manufacturing technologies and set new standards in the bicycle market, especially because innovation is part of the Specialized DNA. OECHSLER’s engineering expertise in product development and manufacturing and its ability to quickly scale prototype and small batch production to high volume production make the polymer specialist an ideal additive manufacturing full-service provider. Currently, the company is exploring new applications besides the saddle with Specialized, aiming to further innovate in the bike market. Carbon provides hardware development and technology, and OECHSLER is the integral full-service partner from development to serial production.

Source: Oechsler

For press release, welcome to send to 3D Science Valley at 2509957133@qq.com

Recent Comments