Skateboard Trucks Tell The Future of Design With Topology Optimization

When it comes to skateboarding, flips and grabs are cool—but downhill longboarding is completely insane. Reaching speeds of more than 90 miles per hour, downhill longboarders combine skateboarding and surfing in an adrenaline blast that is all about speed. Clearly, keeping the wheels attached to the board is critical to these downhill daredevils.

The “truck” of a skateboard is that piece on the underside of the deck that the wheels are attached to. Made of axles, bushes, and pins, the truck is the interface between the wheels and deck that gives the rider the necessary control through shifts in weight, bending and reacting to the board’s travel. It’s a pretty important part, to say the least.

And now, like aircraft parts, furniture, and so many other modern objects, skateboard trucks are set to change, thanks to topology optimization and metal additive manufacturing.

Precision-engineering student and downhill skateboarder Philipp Manger applied his expertise to the skateboard truck because in his words, “It’s the only skateboard part I haven’t made before, and it fit perfectly to try out these new technologies.” But this venture, Project TOST (Topology Optimized Skateboard Trucks), specifically caters to downhill longboarding. Traditional skateboard-truck designs work for skating in the streets, but a style called the reverse-kingpin truck is better for longboarding and high-speed skateboarding.

When it came to redesigning the reverse-kingpin truck, Manger used Autodesk Fusion 360 and Netfabb to aid his optimization. Using Manger’s parameters and constraints for achieving the same (or higher) stiffness while reducing overall weight, the software output an optimized lattice structure. Lattice designs inspired by nature are intricate, bonelike constructions that look like they’ve evolved over millions of years. The improvements in weight, performance, and strength are a big deal in industries such as aerospace, but a skateboard isn’t that heavy—so what kind of performance does a topology-optimized skateboard truck offer?

Most traditional skateboard trucks are aluminium; Manger used the much heavier titanium, but the lattice pattern required far less material, making the truck much lighter. “Titanium has almost double the density of aluminium, so it was a challenge,” he says. “But the big change was that the truck’s upper, moving part—called the hanger—is normally a caster with a steel axle inside an aluminium body. Both of my hanger designs are made out of one part, and the axles are hollow as well, with the lattice going inside the axis.”

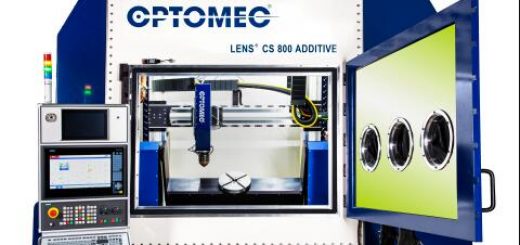

Many topology-optimized parts like Manger’s truck are impossible to manufacture traditionally. Milling or casting techniques don’t have the finesse to remove material amid that tangle of detail. All of the lattice beams in Project TOST prototypes were less than a millimeter wide, which precluded those methods while also giving the project a quantum leap forward. “It was a goal to investigate the limit for metal additive manufacturing, the minimum feature size,” Manger says.

That made the right manufacturing partner critical, and Manger found it in Fraunhofer IWU, a big name in German production-technology R&D. “The Institute’s focus is on metal additive manufacturing and other lightweight designs, so it was the perfect partner,” Manger says. “I was happy to find such a big organization to work with, and they supported me with the access to the building and manufacturing facilities, especially a GE Concept Laser M2, which is a laser-beam-melting machine. It gave me a lot of know-how.”

“The project wasn’t really about creating a skateboard truck,” he says. “It was more about finding new ways for lightweight designs for metal additive manufacturing. Project TOST shows new approaches from the combination of organic forms and lattice structures. The skateboard trucks just happen to be a demonstrator that everyone can understand.”

As yet, Manger has no formal plans to commercialize the futuristic new skateboard truck. It’s not yet economically competitive with traditional truck manufacturing (Manger says it’d take a few more years to get there). Besides, the aim of Project TOST was always to enable a proof of concept.

Resource: Autodesk.com

Recent Comments