3D Printing Industry Executive Survey 2023, Additive Manufacturing Experts Tackle the Greatest Engineering Challenges of the Coming Decade

The 2023 3D Printing Industry Executive survey broadens the scope and asks 3D printing insiders two questions. What is the greatest engineering challenge of the coming decade? What technology will be required to solve this?

Approaches to answering this question varied, some chose to tackle challenges specific to advancing additive manufacturing in the next ten years. At the forefront of executives’ minds are approaches to lowering cost-per-part, ensuring quality is maintained, and how AM can leverage its core advantages to the full? Process Automation and the combination of AI approaches to the additive ecosystem, including intelligent production management systems, part design, and physics-informed neural networks, are covered. How does Moore’s Law relate to 3D printing, and what technologies are on the rise? Tying everything together, a recurrent word: Production.

Other respondees take an alternative approach. What is the bigger picture, and how will technology be deployed to address critical global issues such as decarbonization, the electrification of transportation, green energy production and Industry 4.0? What will combining 3D printing with emerging technologies such as computational material discovery, synthetic biology, or robotics yield?

Again, a broad range of respondees were surveyed, from end users such as Czinger Vehicles to the largest manufacturers of 3D printing systems, software, and materials. And despite the featured image, not one mentioned flying cars. Settle in and enjoy the insights from the experts below.

Engineering challenges for the next decade word cloud. Image by 3D Printing Industry

Engineering challenges for the next decade word cloud. Image by 3D Printing Industry

What do 3D printing experts predict for 2023? Read part one of the annual 3D Printing Industry Executive Survey here.

![]() Dr. Brent Stucker, Chief Technology Officer – Additive Manufacturing, 3D Systems

Dr. Brent Stucker, Chief Technology Officer – Additive Manufacturing, 3D Systems

I believe the greatest engineering challenge of the coming decade will be the electrification of transportation. This is due to the fact that vehicle electrification has significant challenges associated with energy generation, grid stability, distributed charging of vehicles, battery technology, and optimization of vehicle components for electrical propulsion rather than internal combustion propulsion. We are already seeing additive manufacturing (AM) playing a role in each of these areas, but I think there is still a larger role for AM to accelerate vehicle production and performance as well as electricity generation, transmission, and storage.

In order for AM to make an even larger impact, it will be necessary to make significant advancements in technologies, materials, and processes. I think the ability to use multiple materials within one system to build complex multi-material shapes at higher precision and productivity will be a key enabler.

When thinking about energy generation and the grid, the goal is to capture a higher percentage of the incoming energy, whether that’s solar, wind, fossil fuel, hydropower, or nuclear. To achieve more efficient energy capture we need complex metal parts from high-temperature materials. AM facilitates this while also enabling efficiencies through parts consolidation. This will also be useful for key components in the grid such as switches and transformers.

All of that power we’ve now generated and distributed needs to be stored in batteries and efficiently used to power the vehicle. I foresee AM playing a critical role in the production of next-generation batteries and electric motors. Current battery designs involve complex layers of multiple materials; as such a multi-material additive manufacturing approach compatible with battery-relevant materials at battery-relevant feature resolutions could upend battery design. Similarly, electric motors could shift from nearly monolithic designs to integrating coils built into structural elements or other components. This can result in better thermal management as well as reduced weight, which in turn can help improve efficiency and performance. Being able to process several materials within the same 3D printer takes parts consolidation and efficiency to a whole new level for batteries and electric motors. In addition, the standard benefits of AM to other industries, including the ability to bring new products to market more quickly with less assembly and manual labor, can help accelerate electric vehicle transformations as demand increases.

![]() Guy Menchick, Chief Technology Officer, Stratasys

Guy Menchick, Chief Technology Officer, Stratasys

As manufacturers worldwide continue to feel the pressure of increased costs throughout the supply chain, the greatest challenge to overcome, almost universally, is being able to drive down costs to remain competitive. For 3D printing specifically, the same is true: it is critical to continue driving down the cost per part, so that we can continue displacing traditional manufacturing with additive manufacturing in more applications. At the same time, we must maintain and improve essential properties that are critical for performance, such as accuracy, surface finish, and mechanical properties. This is predominantly dependent on two key factors: systems and materials.

In order to drive down system costs, we need to interrupt the tight correlation among inkjet and DLP technologies between resolution, throughput and price. Increasing resolution means smaller drops. Small drops slow throughput. To compensate, more print heads are often added, which increases price. Fortunately, these 3D printing technologies have been following ‘Moore’s Law’, which essentially means that system speeds and capabilities will roughly double every couple of years without any increase to the original prices. In a nutshell, this means that many of the Stratasys solutions currently enabling industrial parts production – from P3 to SAF and more – will all be set to enjoy a significant performance gain in coming years, without this necessarily being reflected in the base cost.

Stratasys’ J35 Pro 3D printer is being used to produce key prototypes for radio products. Photo via Stratasys.

Stratasys’ J35 Pro 3D printer is being used to produce key prototypes for radio products. Photo via Stratasys.

![]() Nikolai Zaepernick, Chief Business Officer & Managing Director, EOS

Nikolai Zaepernick, Chief Business Officer & Managing Director, EOS

A big challenge lies on the cost side. Making the most of additive manufacturing for large-scale production and the sustainability possibilities requires to be mindful of bottom-line concerns. The challenge is to reduce cost-per-part along the entire value chain whilst keeping quality promises.

For a start there is huge potential to reduce cost-per-part and open new applications by reducing supports in metal 3D printing. By shifting to support-free, we are improving the AM process economically, environmentally and with regard to time. (Not needing to construct supports during the build means less of the material in the powder bed will be melted, it increases the build rate and the support removal costs.)

In the future, new support free software tools will help create even better parameters and exposure strategies to further optimize the production process. This will include shorter exposure time, less material consumption and saving post-processing resources.

![]() Frank Carsten Herzog, Founder and Managing Director, HZG Group

Frank Carsten Herzog, Founder and Managing Director, HZG Group

The biggest engineering challenge will be to transfer the processes of 3D printing to industrial production. This involves achieving a high level of reliability, customizability, reproducibility, and speed in AM production, while reducing costs so that it can be used for high-volume manufacturing of parts and products. An enormous task!

When it comes to 3D printers, we will see more machines that successfully combine the advantages of established systems that have so far operated in separate solutions. Precision vs. speed, robustness vs. openness to materials – these points will no longer be mutually exclusive, making technology attractive to a broader range of customers.

There is also a high potential for software. The high manual design effort will be reduced by intelligent software, for example. Users will benefit, as will production, as machines can be controlled more efficiently.

![]() Dr. Gregory Hayes, Senior Vice President Applied Technology, EOS North America

Dr. Gregory Hayes, Senior Vice President Applied Technology, EOS North America

One of the largest engineering challenges we will face as an industry in the coming decade will be the complexity of energy, specifically green energy production and energy storage. Wind, solar, fusion, and fission all have the manufacturing challenges that require additive manufacturing due to their unique and intricately designed components. Further, decreasing energy consumption through distributed manufacturing can aid new energy production by requiring less energy globally. Environmental impact will also be a challenge as we continue forging new solutions, leveraging the beneficial derivative nature of AM to lessen customer organization’s footprint on our environment.

A 3D printed aerospike rocket engine designed using Hyperganic Core. Photo via EOS.

A 3D printed aerospike rocket engine designed using Hyperganic Core. Photo via EOS.

![]() Andre Wegner, CEO, Authentise

Andre Wegner, CEO, Authentise

The greatest engineering challenge is to shorten the time it takes to turn an idea into a part. All other manufacturing and engineering challenges come second to this, as shortening this cycle will allow us to develop better, more sustainable products, adapted to local realities. Three technologies are critical to making this happen:

First, we need to develop a semantic that will allow us to communicate ideas in words, not geometries. Geometrical designs, even annotated ones, are black boxes that clearly communicate only a fraction of the ideas used to generate them. Customer drivers, machine/material restrictions, and engineering experience are all lost. A new semantic that allows us to communicate in words would allow algorithms to determine new options for manufacturing when any input changes – as described below.

Secondly, we need to deliver generalized algorithmic tools that allow us to take the semantic input and define production processes, parameters and designs. These tools are already in development, but are scarcely used beyond topology optimization. This has to change – the speed and volume of data now available to make production decisions from historical, production or in-use sources exceeds human capability and imagination.

Thirdly, we need machines fully capable of expressing their capabilities. Not only as designed, but based on the usage profile and environment. Algorithms must be able to query: Given your usage profile, what tolerance are you able to maintain?, alongside many other queries.

![]() Wayne Davey, Global Head Go-to-Market, HP Personalization and 3D Printing

Wayne Davey, Global Head Go-to-Market, HP Personalization and 3D Printing

One of the most obvious challenges we will face in not just the years, but the months to come, is that of climate change. As we move into the new year, sustainability will continue to remain top of the agenda for brands and businesses alike, which will move away from being just a trend, to a requirement. Therefore, as organisations accelerate their sustainability initiatives, manufacturers, brands and other organisations must be looking at their business and workflow processes holistically, to ensure that they’re delivering end-to-end solutions with a lower environmental impact. That includes everything from the materials they offer and where they source it from and how they recycle or reuse those materials, right through to the manufacturing technology they use and how they deal with waste.

3D printing is a viable option to help companies transform into more sustainable businesses. According to HP’s Digital Manufacturing Trends Report, around 50% of global digital manufacturing and 3D decision makers are interested in exploring the technology further for its impact in promoting a circular economy, and therefore reducing the number of materials used in production and simplifying and creating additional value from production systems.

Additive manufacturing is proving its ability to do so in the packaging industry. It provides an option to help businesses make smarter decisions whilst also utilising more sustainable solutions. Molded fiber is widely recognised as an eco-friendly and biodegradable alternative to traditional plastic packaging, and eliminates the need for harmful material disposal methods.

3D printing technology will need to continue to evolve, opening up opportunities for use in increased industries and for a wider range of products. With the trajectory of the 3D printing industry so far, it seems likely that technology will continue to innovate and upgrade allowing for more exciting use cases to emerge.

A fleet of industrial 3D printers on the production floor – HP Jet Fusion 5200. Image via HP.

A fleet of industrial 3D printers on the production floor – HP Jet Fusion 5200. Image via HP.

![]() Dr. Johannes Homa, CEO, Lithoz

Dr. Johannes Homa, CEO, Lithoz

Over the coming decade there will be a clear “race for efficiency” to overcome the biggest obstacle currently faced by mankind – climate change.

Working towards eco-friendly solutions and overcoming such problems will be the major priority of engineering over the next decade. Sourcing renewable energy, enabling new and more sustainable materials and most of all reducing the amount of energy required during production are the top focuses for companies right now – and the key to it all is higher efficiency.

As such, innovators will increasingly consider ceramics as a powerful and sustainable solution which can keep pace with the demands of technological innovation. The integral advantages of ceramics over metals and polymers in terms of durability, biocompatibility and flexibility prove why they are gaining a growing share of the market and will offer a real boost in the race for efficiency.

From a technological viewpoint, 3D printing will as a first step redesign existing parts to be more efficient. In a second phase, manufacturers will use this technique to create an entirely new generation of sustainable and powerful components.

While this technology will be used to improve parts, it is important to also drive the progress of the technology itself forward. Next generations of 3D printing techniques will be developed and released over the coming decade, allowing for the ever faster realisation of increasingly complex and accurate components.

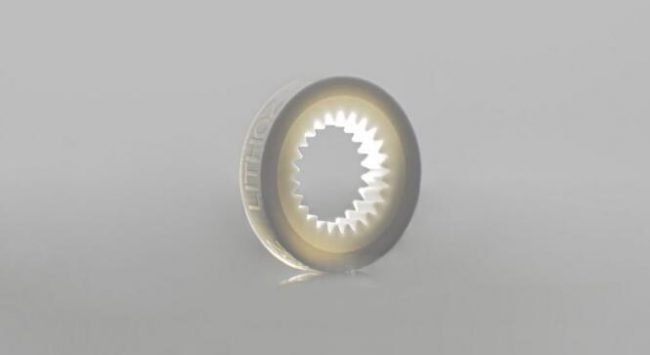

A gear 3D printed using zirconia-toughened alumina and alumina. Each zone has different strength properties. Photo via Lithoz.

A gear 3D printed using zirconia-toughened alumina and alumina. Each zone has different strength properties. Photo via Lithoz.

![]() Bas de Jong, COO, 3YOURMIND

Bas de Jong, COO, 3YOURMIND

As distributed manufacturing models continue to evolve and gain new adoption, one of the biggest engineering challenges will be standardizing production processes for additive manufacturing and qualifying parts to scale. Today, many manufacturers equipped with print-on-demand technology utilize proprietary methods or units of measurement. In a distributed manufacturing model, this practice presents part replication challenges that can vary in quality and performance across production sites or part suppliers.

To resolve this, there needs to be a two-pronged approach. First, there needs to be buy-in from major original equipment manufacturers and material manufacturers to collaborate with standardization organizations to create a unified vision for what practices should be standardized and why. In addition, software and machine vendors will play a critical role in executing these production standards across different software tools while protecting intellectual property information.

Although the challenge is less on engineers to find solutions, it will create a substantial collaborative effort between manufacturing entities protective of design patents and production recipes and vendors and suppliers that provide services across multiple regions or organizations.

![]() Sona Dadhania, 3D Printing Analyst, IDTechEx

Sona Dadhania, 3D Printing Analyst, IDTechEx

Shifting energy infrastructure from fossil-fuel based sources to renewable energy sources is critical to the fight against climate change. There are a whole host of technologies required to implement renewable energy, one of which is energy storage, a topic often discussed at IDTechEx. For example, the demand for batteries for stationary energy storage grows as electrical grids need to store excess electricity generated from energy sources like photovoltaics. Additionally, renewable energy generation capacity, across many sources like solar, wind, and nuclear, needs to dramatically increase to successfully reduce dependence on fossil-fuel generated power.

An important contributor to facilitating this renewable energy transition is additive manufacturing. Not only can additive manufacturing be used to improve the performance, efficiency, and safety of certain sustainable energy sources like wind turbines, but it can also be used to reduce the costs of the installation of renewable energy sources, thus quickening this transition.

Additionally, the traditional benefits of 3D printing such as customization of parts and enabling of localized manufacturing and supply chains will help the renewable energy transition occur globally.

![]() Kevin Nicholds, CEO, Equispheres

Kevin Nicholds, CEO, Equispheres

Over the next decade, we need to transform our production systems and energy usage to a sustainable model. This is a big-picture challenge that won’t have a single solution, but additive manufacturing will be a significant enabler of the range of solutions that bring together more efficient and resilient supply chains, more energy-efficient transportation and production fueled by sustainable energy, higher levels of recyclability and less waste generation.

By permitting more efficient and complex designs, 3D printing enables solutions like improved battery technology and lighter, stronger vehicles. It also has the potential to be a more sustainable manufacturing option, but to realize that advantage at the scale we need requires broader adoption and significantly improved efficiencies.

I think the solution is collaboration. Bring the manufacturing knowledge from folks who have been doing large-scale manufacturing for decades and utilize that knowledge to design AM systems and processes. As AM evolves from primarily a R&D and prototyping technology, we are seeing more teamwork. Both companies and individuals with long histories of manufacturing are looking at the AM paradigm in new ways, and this has led to more innovations.

I think we need to continue to push collaboration between the technology experts and the manufacturing experts to accelerate the adoption of AM in a way that will make it more capable of helping to solve big-picture challenges, by being faster, more cost effective, and more sustainable as a manufacturing process.

![]() John Kawola, CEO, Boston Micro Fabrication

John Kawola, CEO, Boston Micro Fabrication

While there are multiple technical barriers, material science and full closed loop process control need to reach a level to ensure 3D printing can meet technical needs and meet the control/quality requirements manufacturers demand. Most 3D printing materials are approximations of standard engineering grade materials. These approximations need to be more aligned. Process control has been implemented in manufacturing for many years. There needs to be development to more seriously apply this to additive.

![]() Krzysztof Wilk, R&D Director, 3DGence

Krzysztof Wilk, R&D Director, 3DGence

Previous years showed us how fragile current supply chains are. Companies will seek material and logistics savings and maintain a high level of security for components supply. To make this possible, companies will adapt their infrastructure by equipping it with AI-enabled intelligent production management systems, maximizing the efficiency of local and distributed machine parks. The spread of modern manufacturing technologies will allow for the reduction of material inventories. Digitization of warehouses and on-demand production supported with AI, and machine learning, virtual and augmented reality, all of those tools are going to be crucial in modern manufacturing. An essential role in the development of technology will be played by the energy transition, accelerating the emergence of modern solutions that increase energy independence as well as have a positive impact on reducing climate change.

Further, into the coming decade, it will be possible to expect the development of new energy and manufacturing technologies to support the expansion of infrastructure beyond our planet. New production systems, energy storage, automated manufacturing of equipment and spare parts in space or the construction of habitats on other planets using locally available raw materials will allow for an ever-widening expansion of human activities beyond the home planet.

![]() Arjen Evertse, General Manager Sales EMEA, Mimaki Europe

Arjen Evertse, General Manager Sales EMEA, Mimaki Europe

From Mimaki’s perspective, it is expanding on the materials we can use in our 3D printing, which will take our 3D technology to new heights, greatly expanding the possible applications. Ensuring that, no matter the characteristics of the material, they are able to jet through an inkjet head, without compromising on stability or print quality, will be a significant challenge. Knowing what technology will be needed to solve this is certainly another part of that challenge, requiring significant material research and technological development.

Mimaki has turned 3D printing into an art with the Mimaki 3D printer 3DUJ-553. Photo by Michael Petch.

Mimaki has turned 3D printing into an art with the Mimaki 3D printer 3DUJ-553. Photo by Michael Petch.

![]() Ted Sorom, CEO & Co-founder, Mantle

Ted Sorom, CEO & Co-founder, Mantle

The greatest engineering challenge of the coming decade is also the biggest looming opportunity; how to harness the power of artificial intelligence (AI) software to reshape the world of manufacturing. Increasingly, manufacturing equipment is able to gather critical process data, but how to most effectively leverage AI to analyze this data and proactively change manufacturing processes in a way that increases efficiency and productivity, while also reducing costs has yet to be determined.

![]() Dr. Cora Leibig, CEO and Founder, Chromatic 3D Materials

Dr. Cora Leibig, CEO and Founder, Chromatic 3D Materials

The greatest engineering challenge of the coming decade will be creating robotics that can accomplish complex tasks with simple instructions — for example, tools to assist the elderly with household tasks. To achieve this, we’ll need manufacturing technology that can be tailored to meet very specific demands.

![]() Gavin Jeffries, Founder and CTO, Fluicell AB

Gavin Jeffries, Founder and CTO, Fluicell AB

In the last decade, 3D printing has transitioned from being a prototyping tool for aiding the design process, to now being an essential manufacturing technology, enabling functional parts to be manufactured in ways impossible using conventional tooling.

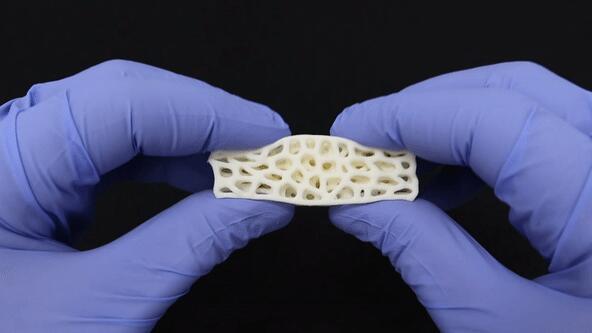

In the coming decade, I would expect to see a similar transition to occur in the 3D bioprinting space, where we will transition away from simple construct demonstrations of printing biological material, to generating essential living tissue sections for pharmaceutical development as well as for therapeutic use. The focus will likely be on patient-specific human tissues, either allogeneic or autologous, with emphasis on establishing personalised bioprinted solutions.

When building patient-specific tissues, 3D bioprinting is only the first step in a complex process. Technologies will need to be established to monitor, quality control, and evaluate the function of one-of-a-kind samples. These will likely need to be non-destructive and ideally non-contact techniques, such as holographic phase microscopes and electrical impedance monitoring, to preserve the integrity and function of the tissues. New delivery technologies will also need to be established to utilise the therapeutic benefits while protecting the tissues from immune responses.

National networks and regulatory bodies are now beginning to participate in this journey, and responses are now being seen by actions such as the 2022 FDA modernisation act and the upswing of entities such as ATMP (Advanced Therapeutic Medical products) networks and 3R (Reduce, Replace, Refine) implementation, both focussing on transitioning toward using designed tissues instead of animals or simple biological systems.

![]() Luo Xiao-fan, CEO, Polymaker

Luo Xiao-fan, CEO, Polymaker

For most additive manufacturing technologies, I think process complexity is still the biggest technical challenge. Unlike most traditional manufacturing technologies, 3D printing has many process variables, and there is a highly coupled relationship between process, material and geometric structure; the traditional process development and optimization paradigm can no longer adapt to the highly complex process characteristics of 3D printing. This has also led to a series of challenges that the 3D printing industry is still facing: process development and optimization take a long time, printing process control is difficult, quality consistency is low, performance is unpredictable, and so on.

To solve this problem, this requires the coordination of many technologies. First of all, we need to improve the construction of the physical model of the printing process. Academia has done a lot of work in the past few years, and it should be said that a good foundation has been laid. What is needed next is to develop simulation software based on these accurate and verified physical models as the main tool for studying the 3D printing process, and at the same time establish a matching, standardized database of equipment, materials and processes. With this foundation, the application of process development, optimization and control can be built based on specific technologies and application requirements; the technical possibilities here are relatively rich, and it can be combined with artificial intelligence and data science to achieve efficient process optimization , It can also be combined with online monitoring of hardware to realize closed-loop control of the printing process, and can also be connected with design software to form a complete closed-loop from design to production.

The realization of the above technologies requires a lot of investment and multi-disciplinary efforts, but this is also the technical threshold that must be solved for additive manufacturing to further realize its potential and truly become a mainstream manufacturing technology. We (Polymaker) have also made a lot of investment and made a lot of progress with many partners in the past few years. In 2023, we will have more profound solutions to face to the market, and here you can also look forward to it.

![]() Hardik Kabaria, Vice President of Software, Carbon

Hardik Kabaria, Vice President of Software, Carbon

There are certain pain points in the design and manufacturing space that will need to be addressed through integrated engineering solutions over the next few years. For example, as engineers design products, there’s a significant amount of manual labor that can be repetitive during the design process for mechanical and electrical components while utilizing CAD and CAE software packages. Just in the last couple of years, there have been significant advancements toward automating design processes to counteract this, with tools like physics-informed neural networks being applied to problems in the CAD and CAE world.

Engineers are also challenged by fragmented processes. Prototyping processes used in the design stage are not connected to the actual manufacturing process, particularly around development timelines and estimated cost per part. This disconnect can lead to friction, limitations on innovation, and delayed time to market. However, there are advancements being made in the additive manufacturing industry that provide more alignment between the prototyping and manufacturing processes, and I anticipate that this will become more streamlined over the next few years. For example, Carbon has created a software solution, Design Engine, that unifies the product design, development, and manufacturing process to help designers and engineers move seamlessly from idea to design and final production.

Similarly, engineers currently need to deal with feedback loops between metrology of the manufactured parts and the intended design that aren’t automated or mature. Our industry as a whole is reinventing the design process for the manufacturers of physical components for products – from printed circuit boards and chips to large mechanical parts like turbine blades and wings for aircraft – so these feedback loops will get better but it will take time. Over time, as the systems and processes develop and mature, product development cycles will become more efficient, advanced, and streamlined, which will help companies create better products and bring them to market faster.

A Carbon 3D printer fleet at an Oechsler facility. Photo via Oechsler.

A Carbon 3D printer fleet at an Oechsler facility. Photo via Oechsler.

![]() Shon Anderson, CEO, B9Creations

Shon Anderson, CEO, B9Creations

As environment, social, and governance (ESG) factors continue to become a growing concern for businesses, sustainability will pose the greatest engineering challenge of the coming decade.

While additive is widely acknowledged as contributing to reducing the manufacturing sector’s impact on the environment, from reduction of waste vs. subtractive manufacturing to reducing carbon footprint and part travel by printing on-site, we will start to see a shift toward companies needing to address their ESG impact – from 3D printed parts through post-processing waste streams.

![]() Eric Bert, SVP Commercial, InkBit

Eric Bert, SVP Commercial, InkBit

Focusing on our own industry, dimensional accuracy, material properties, and cost-per-part are still challenges to be resolved. AM has to be able to compete with traditional manufacturing methods and win on those factors, and I believe high throughput inkjet is the answer in most cases. It is a priority for Inkbit to drive the cost-per-part down and to be competitive with traditional technologies, as well as other AM processes, whilst delivering the dimensional accuracy and overall structural quality people come to AM for. Material properties are also a crucial factor, again designers shouldn’t have to choose between material and form, as they can’t have both because AM doesn’t offer the material but traditional doesn’t allow for complex geometries, AM is supposed to offer true freedom of design, but in truth we’re still working towards that, often because material choice is still limited. And of course this is what we’re working on at Inkbit, our materials are formulated for durability, to be impact-resistant and withstand long-term UV exposure, and we’re developing more all the time; we use closed-loop feedback control to guarantee repeatable dimensional accuracy and the productivity of our system helps us to deliver very competitive cost-per-part.

Inkbit’s 3D printer can produce multi material objects at high volumes. Clip via Inkbit.

Inkbit’s 3D printer can produce multi material objects at high volumes. Clip via Inkbit.

![]() Alessio Lorusso, CEO & Founder, Roboze

Alessio Lorusso, CEO & Founder, Roboze

Our experience in the additive manufacturing of parts with high-performance thermoplastic materials has demonstrated in recent years its ability to integrate into traditional production processes, offering as the first tangible advantage in the short term the reduction of production costs and delivery times.

The next 10 years will be key in increasing end-user awareness of the benefits of industrial additive manufacturing. This will lead to new challenges that we think will be played out on two distinct levels: sustainability and the integration of technology into all stages of production. Roboze is already working on both fronts, proposing not only innovative technologies and materials, favored by our strong nature in the research and development of completely new and competitive ecosystems, but also more sustainable business and financial models.

![]() Feng Hua, Founder & CEO, Raise3D

Feng Hua, Founder & CEO, Raise3D

After the development of the 3D printing market in the past thirty years, what are the challenges for the next ten years? I would like to summarize using the TOE concept: T means Technology, O means Organization structure, E means Environment system. In the future, from the three aspects, whether it is possible to apply 3D printing to specific commercial applications will be the biggest challenge for the market.

In terms of technology, it includes the choice of technical route, possible iterations of technology, whether automation can support it, how to combine with traditional CNC, or partially replace traditional manufacturing methods. At the commercial level, the organizational structure of the enterprise needs to be in line with the development pace to absorb new technology such as 3D printing, it is important for the organization to measure whether having a certain tolerance for innovation failure and whether the profit from re-innovation meets with the expectation or whether the cost reduction is worth the efforts of adopting 3D printing technology. In addition, in terms of environment, there are differences in the culture between Europe, the United States, and China. Furthermore, differences in fields, industries, and companies will be the biggest challenge for implementing 3D printing in the next ten years.

![]() Jason Fullmer, Chief Operating Officer, Formlabs

Jason Fullmer, Chief Operating Officer, Formlabs

The greatest engineering challenges in the coming decade are supporting the increasing demand for mass customization and designing supply chains for new technologies that are faster, more nimble, and equally as cost-effective as today’s systems. 3D printing supports both of these challenges, enabling efficient, cost-effective onshore production and providing the ability to customize consumer guides at scale without increasing material or labor costs.

For example, Formlabs Automation Ecosystem provides a three-time increase in productivity while saving up to 80% on labor, lowering cost per part by 40%, and reducing packaging waste up to 96%. With the ability to manage multi-user, multi-material printer fleets, the Automation Ecosystem enables continuous production so users can send multiple prints to run overnight and into the weekend, making mass production a reality.

![]() Philipp Kramer, CTO & Co-founder, DyeMansion

Philipp Kramer, CTO & Co-founder, DyeMansion

Even as devices become more energy efficient, we are facing a huge rise in demand for energy due to population growth and rising incomes, resulting in more money being spent on products and services. We often rely on new technologies to fight climate change, but the improvement of already existing technologies will have a huge impact as well.

Planning, manufacturing, and installing sustainable energy sources, such as solar panels or batteries, requires highly skilled people and a lot of effort. Let’s take installing solar panels on the roof of our house as an example. Somebody needs to plan it, parts need to be manufactured, and highly trained technicians need to install it. Automating parts of this process and reducing the need for skilled people (e.g., via AR) will be key to meeting the rising energy demand.

DyeMansion’s VaporFuse surfacing system, the Powerfuse S, has received two new process innovations. Photo via DyeMansion.

DyeMansion’s VaporFuse surfacing system, the Powerfuse S, has received two new process innovations. Photo via DyeMansion.

![]() Dr. Vladimir Navrotsky, Additive Manufacturing Chief of Technology, Siemens Energy

Dr. Vladimir Navrotsky, Additive Manufacturing Chief of Technology, Siemens Energy

The greatest engineering challenges of the coming decade are undoubtedly the decarbonization of industries and the energy transition. I strongly believe that additive manufacturing will play a significant role in solving this challenge.

Gas turbines that run on biofuels and green hydrogen will still be needed in the future energy mix. AM-designed gas turbine burners allow even installed turbines to be upgraded so they can use of up to 100 percent hydrogen. AM-designed and manufactured high-temperature alloy turbines blades and vanes will significantly increase turbine efficiency and as a result reduce fuel consumption and emissions.

Using AM to produce fuel cells and heat exchanges will drastically enhance their efficiency and reliability.

Finally, recycling AM components will reduce material demand and emissions.

![]() Max Siebert, CEO, Replique

Max Siebert, CEO, Replique

I see two major challenges for the engineering industry: persistent supply chain disruptions and climate change. Decentralised manufacturing with a digital inventory can play a critical role in developing greener and more resilient processes by eliminating physical inventory and producing only the quantity needed, anytime, anywhere. 3D printing has already established itself as a serious production method to achieve this goal. However, in the coming years, more training and education in companies and universities will be required to truly scale up. In addition, costs must come down for 3D printing to be used in mass production. In my eyes, pellet printing is an innovative example of how cost reduction can be achieved by streamlining the material manufacturing process to fewer steps.

![]() Paul Holt, Founder, Photocentric

Paul Holt, Founder, Photocentric

The biggest challenge in engineering is to develop sustainable solutions for automated mass manufacture. Key to success will be the development of smart software that increases process efficiency in terms of energy, time and materials savings through the use of big data. From a hardware viewpoint, the design of modular systems that are scalable will be the answer to fulfil the needs of parts on demand. Finally, creating recyclable materials suited to the industrial requirements for mass production will complete the ecosystem.

![]() Xavier Martínez Faneca, CEO, BCN3D

Xavier Martínez Faneca, CEO, BCN3D

One of the biggest challenges facing manufacturing in the coming decade is the need for greater autonomy and control in the production process. This includes the ability to produce products locally, customize them to meet specific needs, and have more control over supply chains. However, currently, 3D printing technologies have not yet reached the level of maturity needed to fully unlock this potential.

One solution to this challenge is the development of advanced 3D printing technologies that could become the pivotal point of manufacturing, such as VLM (Viscous Lithography Manufacturing). This technology has the potential to give companies full control over the fabrication life-cycle of their products, from design to final production.

![]() Ao Danjun, CEO, Creality

Ao Danjun, CEO, Creality

The greatest challenge is how to achieve 5-10 times higher printing speed than the current one while balancing print quality and ensuring success rate. In addition, the range of printing materials for high-speed 3D printers, especially industrial-grade 3D printing materials, needs to be expanded. 3D printing is a multidisciplinary technology that involves efforts from multiple sides. We will work with partners in various fields to create a synergy and empower Industry 4.0 by leveraging the power of 3D printing.

![]() Doug Kenik, Director, SW Product Management, Markforged

Doug Kenik, Director, SW Product Management, Markforged

As we look at the manufacturing landscape and the evolution of requirements over the past years, we see the industry heading in an exciting direction. Two emerging trends will influence the industry: supply chain disruption and localization to increase efficiency, and the speed of development in a digital world – which has yet to be matched in the physical world.

The collision of these two trends will surface a manufacturing and engineering challenge, demanding further manufacturing disruption to increase efficiencies and bridge the gap between physical and digital in a shorter amount of time. This is a manifestation of on-demand requirements at scale, as well as business drivers to iterate quickly and suppress costly overhead.

Overcoming this challenge will require maturing localized manufacturing, such as additive manufacturing, to augment traditional processes, and combine it with digital automation through data and software to increase efficiencies in traditional and emerging manufacturing. Efficiencies through automation will be realized quickly but can only be leveraged with the correct combination of data and software.

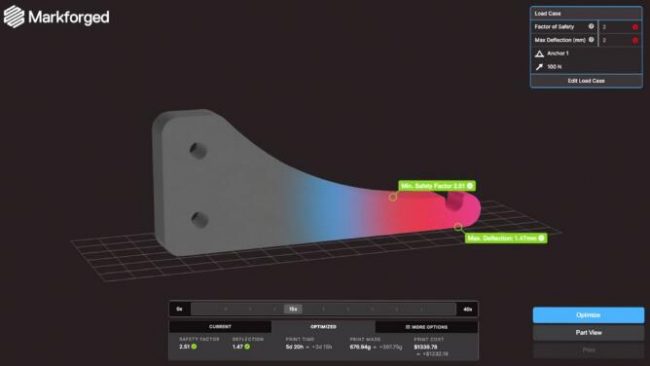

A screenshot of the UI when using the Simulation feature on Markforged’s Eiger software. Image via Markforged.

A screenshot of the UI when using the Simulation feature on Markforged’s Eiger software. Image via Markforged.

![]() Jason Vagnozzi, Global Vice President of Additive Manufacturing, Braskem

Jason Vagnozzi, Global Vice President of Additive Manufacturing, Braskem

The promotion of green engineering to reduce the carbon footprint of traditional manufacturing is an important trend we are keeping a close eye on. We believe that additive manufacturing can help play a key role in helping companies to develop a more sustainable approach to manufacturing.

![]() Steffen Schmidt, CTO, Danish AM Hub

Steffen Schmidt, CTO, Danish AM Hub

Real sustainable manufacturing will be a big challenge. Too many companies greenwash their image with minor changes to their internal energy usage in their own production and are satisfied with only this minor effort. But they seldom address the real challenge: To change the products they produce and how they produce it.

The Scope1 and 2 emission reductions are more or less of a one-off – not bringing a continuous reduction to our global CO2 emissions.

The only way to change this is by knowledge, so both the customer and the manufacturer know of and acknowledge the importance of sustainable products and production. Training and dissemination of knowledge are key, and every manufacturer of 3D printers, CAD, and 3D print-related software needs to implement and support this.

![]() Professor Moataz Attallah, The Advanced Materials Processing Lab. (AMPLAB), University of Birmingham

Professor Moataz Attallah, The Advanced Materials Processing Lab. (AMPLAB), University of Birmingham

The Ukrainian-Russian war has identified sustainable energy as the key engineering challenge. 3D printing may play a great role in speeding up the uptake of both renewable and sustainable energy sources. I hope to see 3D printing being used in the construction of nuclear reactors and their components, either by concrete 3D printing or 3D printing of reactor components. A key game changer would be the development of nuclear fusion. 3D printing can be used to produce the components that are meant to handle the extreme conditions in nuclear fusion, particularly the cooled plasma-facing components.

![]() Sylvia Monsheimer, Head of Industrial 3D Printing, Evonik Industries AG

Sylvia Monsheimer, Head of Industrial 3D Printing, Evonik Industries AG

A major engineering challenge in the next decade will be realizing the first large-scale industrial lighthouse applications. Admittedly, this presupposes various aspects such as faster processes, more application-specific materials, data handling and automation along the entire production chain as well as proven scaling effects. In the end, no single technology will be able to unbind 3D printing at scale – it is more of an integrated production chain which is the decisive point. At Evonik, we expect a decade of new infinite 3D applications across all industries contributing to our capability to develop the right high-performance materials and expand our production capacities along the market growth to create trust and actively shape the market and thus being always stay one step ahead.

![]() Alexandre d’Orsetti, CEO, Sculpteo

Alexandre d’Orsetti, CEO, Sculpteo

The greatest challenge of the upcoming decade will be in the design, and availability of 3D models. We’ve seen a vast hardware expansion in the past, but 3D models are still somehow complicated to make. Nevertheless, we are starting to see some automation in the modeling of 3D files, as well as powerful simulation tools that are required to convince the market and provide reliability on parts.

Machine manufacturers, material developers, and service providers have a main challenge of constantly improving the technology to meet the repeatability, quality, properties, and cost per part which are requested by customers to unlock new applications and especially bigger series.

![]() Gareth Neal, Business Development Manager EMEA & Israel, 3D Printing & Advanced Applications, Xaar

Gareth Neal, Business Development Manager EMEA & Israel, 3D Printing & Advanced Applications, Xaar

In one word – energy! The development of energy solutions, from solid state batteries to hydrogen fuel cells, and the role that digital manufacturing techniques can play in enabling these technologies and markets will be increasingly important over the next decade.

The ability to digitally print any shape, to exacting specifications with appropriate materials will save time and significantly reduce costs in relation to today’s analogue processes. Here new capabilities such as Xaar’s High Viscosity Technology and particle loading capability will enable developments at a usable resolution and speed, driving new Additive Manufacturing applications in this growing sector.

![]() Greg Brown, VP of Technology, Velo3D

Greg Brown, VP of Technology, Velo3D

Thermal management/distortion as systems get more productive and parts get larger and hotter. Some legacy solutions to these problems on smaller systems (eg. utilizing thick build plates to prevent part deformation, adding machining stock to parts, “ghost parts” to avoid part overheating) are not keeping up as systems get bigger and faster. Tight integration of part slicing, in-situ metrology, hardware and simulation are going to be needed to continue pushing up system productivity and lowering printed $/kg while maintaining high quality associated with laser powder bed fusion.

Aerospace components 3D printed on a Sapphire system. Image via VELO3D.

Aerospace components 3D printed on a Sapphire system. Image via VELO3D.

![]() Dr. Gerald Mitteramskogler, CEO, Incus

Dr. Gerald Mitteramskogler, CEO, Incus

One of the upcoming challenges for the European industry is to reach energy and climate targets for 2030 with carbon footprint mitigation. 3D printing in general will help to develop the best technological solutions. At Incus, we highly believe that our Lithography-based Metal Manufacturing technology will enable innovation, and there will be an Incus product involved in solving future challenges.

![]() Ewan Baldry, Chief Engineer, Czinger Vehicles

Ewan Baldry, Chief Engineer, Czinger Vehicles

Scaling the technology is probably the greatest challenge, but one that is being met head-on by Divergent and Czinger. In 2022 alone, we have seen vast improvements in all aspects of the technology from design, printing, postprocessing, and automated assembly – new materials, new machines, new processes, all developed in-house. What seems clear is that making significant progress requires a holistic approach. At Divergent, we have engineers and technologists addressing everything that contributes to the increasing commercial viability of the technology’s application. Engineers and technologists who are laser-focused on all areas, from materials scientists developing the powders we print, surface treatments we use, and adhesives we bond with, to AM engineers contributing to the design and development of the printers we use and the most efficient use of those printers, software/CAE/optimization engineers who are accelerating the design process to allow us to exploit the real power of 3D printing and so produce components and assemblies that are optimized in terms of the material and energy that is needed to create them. We lucky people at Czinger have all this technology at our fingertips that we are using to create a hypercar that we believe has so many “world’s firsts,” demonstrating one of our brand pillars, “Revolutionary Technology.”

The relationship between Divergent and Czinger (we are all on the same site in Torrance) offers a unique, symbiotic opportunity on many levels. In creating products, Czinger’s demands/ desires help to drive the technology that Divergent is creating – Czinger engineers push the Divergent team to enable the realization of their ideas. In Czinger, Divergent has an in-house, real-world application to hone and validate their technology and, in turn, offer it to the broader automotive industry – a trickle-down effect. It is the creation of companies like Divergent and Czinger, focused on figuring it all out and not just bits of it that will enable the technology to scale and become the way all things are made in the future.

![]() Vadim Fomichev, Sales Director, Thor3D

Vadim Fomichev, Sales Director, Thor3D

3D printing offers huge opportunities for manufacturers and our forecast assumes that not only small businesses, but also heavy industry is interested in mastering 3D printers. On a big scale swift mass production is crucial, and printing speed remains a challenge. To overcome the limits of 3D printing speed, the engineers have to solve probably the biggest dilemma of their life. Sometimes the nozzle has to go slow to allow the substance to cool down, so you can add the next layer, yet mass production demands to follow strict deadlines.

The second challenge is self-sufficiency. Think of modern assembly lines, where robotic manipulators do the job? A dozen of these robots need only one operator. Will the engineers be able to make 3D printers automatic and reliable enough, so a big production will need only one or two operators to manage them?

![]() Carlos Zwikker, Chief Commercial Officer, AM-Flow

Carlos Zwikker, Chief Commercial Officer, AM-Flow

The greatest engineering challenge of the coming decade will be that of creating Smart AM Factories. In the past, we have focused on the main message that the key driver to growing the AM market is reducing cost per part. And we believe this is still true now and most likely to continue to be a relevant message in the coming years. Although the market keeps growing, scaling AM output is inhibited by manual labor. The cost of manual labor is an inhibitive factor in scaling AM production output. Workflow automation is a prerequisite to reducing cost per part and is the basis of creating Smart AM Factories. And the reduced cost per part brings us to more applications with a viable business case, and these viable business cases are what drive further growth.

The engineering challenge for the next decade will be to move from non-communicating verticals – MES platform, printer, post-processing workstations, etc. – to a fully connected end-to-end digital thread throughout an AM production facility.

We are just at the beginning of this journey as this journey runs in parallel with the maturity of printing technology and AM manufacturing processes. AM-Flow sees itself as a driving force and the provider of hard- & software workflow automation solutions for the Smart AM Factory of the future, and we proactively seek collaboration with all other companies contributing to the digital chain of events of the Smart AM Factory of tomorrow. We think there will be closer collaboration between all companies addressing the puzzle of automating 3D print factories. For the end customer, building a Smart AM Factory is more than just acquiring more printers, several post-processing units, workflow automation, etc.

![]() François Leclerc, Program Manager, Creaform

François Leclerc, Program Manager, Creaform

The upcoming decade will undoubtedly be filled with many challenges, one of which appears to be time to market, i.e., the time required to develop and produce new (or newer generation) products. With workforce getting more and more sparce, there will be an increasing pressure on businesses to develop products faster.

Any technology helping to speed product development will inevitably help to solve this problem. Of course, 3D scanning being a major asset when it comes to bringing existing objects into digital processes will certainly be a major contributor. Once data has been captured with a 3D scanner, software to process and use the data will also be a critical aspect to consider. Every step of the process will be more and more critical, and no waste of time will be acceptable.

![]() Sam O’Leary, CEO, SLM Solutions

Sam O’Leary, CEO, SLM Solutions

I’m not sure I can tell you the problem, but I can tell you that whatever it is, we will find a way to solve it through collaboration, innovation, and open architecture.

![]() François Leclerc, Program Manager, Creaform

François Leclerc, Program Manager, Creaform

The future of 3D printing will be industrial or not, that’s the challenge. This is why at 3DCeram we have made a technological choice, that of the automatable top down. This choice is unquestionable in an industrial context for mass production. We know that in order to produce a lot, you need large build platforms, which are also versatile and on which it is also possible to print big parts!

As we know, moving to the industrial stage implies a production rate which requires automation of the process. And this will have to be done with a user-friendly software interface, the different stages of 3D printing will then be controlled in an intelligent way, with AI, launching the run and monitoring the printing, then automated filtration and cleaning systems, to obtain the final part, ready for firing!

At Formnext, in November, we presented a semi-automatic line that will enable relevant production rates to be reached with few personnel, for manufacturers who wish to integrate 3D printing into their production workshops.

![]() Ma Jin-song, General Manager, UnionTech

Ma Jin-song, General Manager, UnionTech

The major challenge is realizing product performance through production requirements, which means high efficiency, high consistency, and high stability with low cost, in the middle and long run, to realizing distributive manufacturing.

Solutions include:

1. Design: Adoption of new design platforms, DfAM, etc.

2. Material breakthrough: 3D printing materials, as the driving force for the development of the 3D printing industry, have always played a pivotal role in the development of the industry. Therefore, 3D printing materials are an important basis for developing 3D printing technology. To a certain extent, the development of materials is one of the main factors which determine whether 3D printing can have a wider application.

We expect that in 2023 and the future, the material properties, implementation of gradient materials, and multi-material printing will be further developed.

3. Printing costs will be lowered further lowered to meet the trend for greater volumes in production.

4. Post-processing technology will be further developed: currently the post-processing is complex and costly

5. Digital manufacturing process chain will be further enhanced to incorporate the demand for agile business models shaped by 3D printing.

6. The trend of equipment’s inter-communication, as well as parameter sets, will be required as the process chain gets integrated.

![]() Li Tao, Chairman & CEO, Shining 3D

Li Tao, Chairman & CEO, Shining 3D

The engineering challenge is “accuracy” and “speed.” It is mainly reflected in the challenge of achieving fast, stable, and consistent manufacturing capabilities. How to achieve product quality consistency and improve the standardization of the manufacturing process is also the value that Shining 3D focuses on when positioning each product and solution to the market. In particular, compared with the process of subtractive manufacturing and mold manufacturing, the 3D printing process has more variables in terms of controlling the quality of printed products. How to monitor and trace the quality of the whole process will be a system engineering challenge, which involves the comprehensive application of engineering technologies such as various sensors, 3D measurement of internal structure and appearance, plus the analysis ability provided by software algorithms and AI.

The natural beauty of 3D printing lies in manufacturing more complex organic structures. With the increasingly stringent requirements on the quality control of printed parts, this also poses higher challenges to the two-dimensional imager and three-coordinate dimension measurement technology. Therefore, Shining 3D high-precision 3D scanning and inspection solutions are also being used more and more in the full-scale measurement of additively manufactured parts. To meet the fast-lane development of the value chain, it is believed that the systematic integration of various engineering technologies related to quality control is critically important.

![]() Gui Pei-yan, CEO, HeyGears

Gui Pei-yan, CEO, HeyGears

The development and application of a digital chain is a significant challenge that must be faced in the development of additive manufacturing because data is the key element throughout intelligent production.

To deal with challenges, two issues are closely related. On the one hand, the digital chain requires the effective connection of 3D printing hardware with software to form an integrated and digital solution based on actual application requirements. Therefore, professional technologies such as digital material, artificial intelligence, software, and big data processing are worthy of attention and investment.

On the other hand, consideration should be given to the consumer’s mindset. In the medium and long term, the increase in consumer consumption patterns and changes in consumption habits will create a higher level of demand for 3D printing applications. This will enhance the development and growth of high-tech 3D printing commodities and high-quality service providers. The popularization path of technology can be traced, with the landing and promotion of digital applications in more fields, 3D printing will play a bigger role in our life, bringing more convenience and benefits.

It is necessary to deal with the challenges through investment in technology research and development, to attract, reserve, and continuously invest in talents. Technological development can bring beautiful changes to people’s lives. The key point is to always start from application requirements, combine industrial capabilities with underlying 3D printing digital technology, and intelligently integrate production processes such as data collection, data management, model design, 3D printing equipment, 3D printing materials, and post-processing.

The popularization of lowering the barrier of applied 3D printing technology compared with the research and development efforts aimed at the high-end intelligent manufacturing market will co-exist. With the continuous development of 3D printing products for new applications, I believe that the 3D printing industry will bring more benefits to people in the future.

![]() Jin Tian-shi, Managing Director, Voxeljet China

Jin Tian-shi, Managing Director, Voxeljet China

The next ten years will be a decade that additive manufacturing technology, and customer needs, will interact and shape each other.

The value logic of 3D printing is model-free and high-performance. In this decade, we will see 3D printing and traditional manufacturing get work together with each other.

The main challenge for 3D printing for mass production applications is to reduce the overall cost, to improve the stability of the equipment, and to ensure the consistency of the quality of printed products.

To solve these problems, we must focus on the continuous comprehensive improvement of equipment, materials, processes, and automation.

Taking sand mold printing as an example, we will see the emerge of mass production projects of complex sand cores with an annual output of 10,000 pieces and super large sand molds with a single piece of 10 meters big and a single weight of more than 100 tons.

In order to meet the above requirements, technologies such as sand material recycling, robots, automatic detection, automatic logistics, and new post-processing techniques will emerge and be gradually promoted and applied.

![]() Roger Uceda, Technology Transfer Director, CIM UPC

Roger Uceda, Technology Transfer Director, CIM UPC

The biggest challenge for the next 10 years will not be to produce a part using 3D printing that meets the requirements for which it has been designed, but to manufacture thousands or millions of parts, with complete confidence that all of them will meet these requirements.

For this reason it is necessary to work on two aspects, the first is standardization, essential to give legal coverage to those products that we manufacture. And the second, more important, is to be sure that the parts we produce actually have the right mechanical, thermal, optical… properties. In the case of 3D printing, knowledge in manufacturing processes and materials will not be enough. The particularities of this technology will require full traceability of the material used, as well as each and every parameter with which it has been manufactured. In CIM UPC we work not only to develop new 3D printing technologies, but in all that involves modeling parts that are being manufactured, with real-time monitoring systems that allow full traceability on the process, being able to guarantee that 100% of the parts that are manufactured are within specifications.

![]() James DeMuth, CEO, Seurat Technologies

James DeMuth, CEO, Seurat Technologies

Generating massive amounts of clean energy is going to be one of our greatest challenges for many decades to come. Followed close behind by access to material resources. There are of course many technologies that will take part in solving this, initially focused on intermittent renewables such as solar, wind, and tidal, evolving to steady load generating sources such as geothermal, hydro, and ultimately nuclear fusion. The race is still on to determine which solutions to fusion (and geothermal) will be the most effective, but the world will benefit from competition and a diverse solution set. If history has taught us anything, it is that we often find our greatest discoveries not in what we are seeking, but what we find along the way. The technologies that result from the pursuit of fusion (next-gen lasers, next-gen high power magnetics) will have untold applications that unlock new potentials and capabilities. Our company, Seurat, was born out of the pursuit of fusion, leveraging the lasers for fusion, but applied to material processing to achieve high throughput, high quality, and economical part production competing with conventional manufacturing.

![]() Joan Horvath and Rich Cameron, co-founders, Nonscriptum LLC

Joan Horvath and Rich Cameron, co-founders, Nonscriptum LLC

Assuming we are focusing on just engineering challenges in the 3D printing universe, the first few decades of 3D printer development were focused largely on hardware development and experimentation. The last five years or so have mostly been driven by new materials innovation. The next frontier is reliability and ease of use, and we expect software to automate some of the know-how of expert users will be the next big set of improvements. Advances in AI and in machine vision may make key contributions to automated slicing, printing, and part validation in the next decade.

![]() David J Webb, 50th Anniversary Professor of Photonics, Aston University

David J Webb, 50th Anniversary Professor of Photonics, Aston University

Aging workforce is a problem in engineering many Engineers are in 40-60 years age group, with no experience of additive even 30+ have little this means more education is needed to show the benefits of additive as an engineering solution so the promotion of additional courses for people already in the workplace such as CPD will be seen as essential moving forward.

Education needs to be on both software and technology advancement and needs to be considered as a mainstream manufacturing technology not hobbyist or for research based

This applies also to the medical community where 3D software like “Mimix” is being used to view CT and MRI scans to help in surgery. Additive can help take this further by using techniques for slicing and printing to produce 3D models of patients’ bones, organs and veins, again to help in diagnosis and surgery

![]() Ryohei Yuasa, Researcher, Head of material design Digital Manufacturing and Design Research Center for Emergent Circularity, Keio University

Ryohei Yuasa, Researcher, Head of material design Digital Manufacturing and Design Research Center for Emergent Circularity, Keio University

We will see an acceleration of attempts to link materials, products, and social systems, such as the Digital Product Passport. More and more products will be made with detailed information on materials and design to reduce the burden of recycling and disposal. Companies will be asked whether they are able to disclose information on the grade name level of the materials they use.

![]() Aurélien Fussel, 3D Printing Program Manager + Additive Manufacturing Senior Expert

Aurélien Fussel, 3D Printing Program Manager + Additive Manufacturing Senior Expert

Services Operations, Alstom

The three main challenges are: training, training and… training. I do my best to support the change of mindset regarding design rules for 3D printing (DfAM) by organising elearning, webinars and classrooms. From a simulation software point of view, Finite Element parameters are more and more mature even if final validation on the test bench is still mandatory for critical 3D-printed parts. The fastest change occurs when people are touching 3Dprinted parts and asking how they can use this technology daily.

![]() Taso Arima, CEO and Co-Founder, IperionX

Taso Arima, CEO and Co-Founder, IperionX

The next decade will not only bring significant challenges to the field of engineering but also to supply chain management, This includes resource scarcity and efficiency. With a finite supply of raw materials, recycling and reusing materials is a crucial strategy for meeting the growing demand of consumers. The implementation of circular technologies is an essential solution for preserving natural resources and ensuring sustainable production.

Take your smartphone as an example, the average device uses an array of critical minerals including copper, tellurium, lithium, cobalt, manganese, tungsten, and more. As demand for smartphones and other consumer electronics grows, so does the strain on the supply of these critical minerals. The UN reports that only 20% of e-waste is recycled annually, leaving the rest to fill and contaminate our landfills. Implementing circular technologies is necessary to reduce our impact on the environment for both the extraction of mineral resources and their post-consumer lifetimes.

![]() Frank Roberts, President, 6K Additive

Frank Roberts, President, 6K Additive

Additive manufacturing included, of course, but also with conventional manufacturing, the appetite for more advanced materials will continue to be a focus for many advanced applications. However, the emphasis on ESG will continue to rise as countries and individual companies add more regulations and emphasis on carbon footprint. The intersection of the two issues is where the challenge will grow. A newly developed material may not meet the ESG requirements, and/or the production method may cause environmental issues. Does the mere fact that its new or that its sustainable drive the price point too high for volume production? Cost and sustainability will all need to converge to bring new materials with a sustainable element to market.

Geo-political events, wars, pandemics, and semiconductor chip shortages have all brought supply chain volatility to the forefront of challenges across the globe. A focus not only for the US but for every country is supply chain independence and the ability to recycle material that already exists in many places, including retired military equipment, end-of-life parts, and subtractive technology machine shops, to name a few. The ability to recover precious metals that exist in these components is one challenge, but also the ability to convert the materials back into a usable product at costs that are actually lower than virgin material will present a second challenge. Leapfrog technologies will be key to helping to process critical materials for new applications we haven’t even seen yet.

![]() Ian Falconer, Founder, Fishy Filaments

Ian Falconer, Founder, Fishy Filaments

Climate change.

Direct capture of carbon emissions will be required to bridge the divide between the global haves and have nots, but its no excuse for the haves to ignore technologies and practices that minimise future carbon emissions. We need to link capture with utilisation as an oil replacement.

Direct atmospheric and industrial capture of emissions is a waste management issue every bit as much as it is a technological development issue.

In recent years we’ve seen public perception change with regards to using the ocean as a general dump for land based waste.

There is an analogy with using the atmosphere as a dump for industrial waste gases but the public does not yet make that same connection, perhaps because we don’t see songbirds wrapped in solid bands of CO2 and we can’t organise community-level CO2 picks that empower individuals. There is no positive end of the physical engagement spectrum for carbon emissions, only geographic or population-level negative impacts, and that limits how the communicating professions can direct attention to the issue.

So we need to see a set of tech that enables direct capture and re-use of carbon and methane emissions by businesses and organisations, but without the need to mobilise the general public. That means they have to be cheap or preferably profitable. Storage through materialisation and resale, rather than burial, is a means to replace crude oil and natural gas and that might enable profitable carbon capture without excessive taxpayer subsidy.

![]() Franco Cevolini, CEO, CRP Technology

Franco Cevolini, CEO, CRP Technology

From my perspective, the challenges that we shall face are a few. Even if some of them are less immediate or less obvious, they can still lead to great benefits and an effective strategy.

The first concerns the switch to an efficient production level where all the stages and issues typical of the mass production process have to be properly addressed: from efficient order execution to packaging and production process optimization.

We as a group are investing not only in new technological solutions but in a combination of technological upgrade with personnel skills implementation.

Now more than ever, achieving excellence requires an understanding of production impact in terms of parts reliability. This is and has always been a focal issue of additive manufacturing, where a variety of factors have to be carefully categorized, controlled, and thoroughly monitored.

Quality system in the Additive Manufacturing process still represents a long path where a complete array of activities have to be focused, coordinated and deployed.

Among these Process Automation is acquiring huge importance. The additive technology has evolved, and its possible applications are constantly growing with the adoption of new models. Of course this expansion needs to be guided and requires setting new routines to improve the results already achieved. This is a delicate upgrade as automation is commonly connected to large-scale numbers while here, it has to coexist with low volumes and quite a few variables playing an important role.

![]() Stephan Beyer, Co-founder & Chief Venture Officer, nFrontier

Stephan Beyer, Co-founder & Chief Venture Officer, nFrontier

Quality of parts, costs, availability are key and can be solved with the existing technologies….no need to invent more of them.

But two true and remaining challenges remain. Sustainability and digital. Automated design, digital twins, CAM / PLM integration are just a few open issues where digital tools still have to be developed. Secondly, AM still has to prove its impact on sustainability, not only green washing.

![]() John Olhoft, President, LulzBot

John Olhoft, President, LulzBot

Bridging the gap between 3D Design and physical object creation. As it stands right now there are a large number of remarkable innovators and engineers that are either too intimidated by or lack the time to invest in 3D Design. I believe that more intuitive software, coupled with the quick wins available with 3D Printing, will help to make 3D Design less of a hurdle during the next decade.

![]() John E. Barnes, Managing Director, and Laura Ely, Director of Programs, The Barnes Global Advisors

John E. Barnes, Managing Director, and Laura Ely, Director of Programs, The Barnes Global Advisors

The greatest engineering challenge is here: Creating the right team. How do we create technical teams with the right skills to solve complex problems of the decade? How do we inform management whose job it is to sustain the business with increasingly complex technical evolutions? The future is the team. The future is knowledge. And the future is technology. But technology without knowledge to absorb, understand and utilize is pointless. The future is a team sport because the future is complex. We need more brains, and we need more openness to tap into the brain potential regardless of sex, race, religion, or anything else. We just need brains that are interested in solving these problems.

![]() Steven Camilleri, CTO and Co-Founder, SPEE3D

Steven Camilleri, CTO and Co-Founder, SPEE3D

One of the key issues is the development of new technology that solves problems more sustainably than before with better efficiency and less waste and excess. This should be a key goal, especially for the 3D printing industry. For example, 3D printing should not be limited to just creating new parts; it should also be used more and more for repairing, restoring and modifying parts. Solving problems by making parts close to the point of need eliminates the transport energy and emissions that would otherwise be needed to move the parts around. Metal 3D printing, (particularly our cold spray process,) is one of the most efficient ways to do this since it produces parts responsibly, quickly and inexpensively. Technologies need to be developed that allow the simple and convenient manufacture of new parts using material recovered from old parts – this is really only possible at the moment with metal materials. All of the trends point to a continued increase in attention toward 3D printing as a tool for making parts and solving problems more sustainably.

![]() Joshua M. Pearce, Ph.D., John M. Thompson Chair in Information Technology and Innovation, Western University

Joshua M. Pearce, Ph.D., John M. Thompson Chair in Information Technology and Innovation, Western University

The greatest challenge we have is to eliminate our dependence on fossil fuels, their pollution and thus climate destabilization. We can do this with a combination of solar photovoltaics, which already produce the least expensive electricity on the planet and offset coal (coal air pollution already kills 52,000 Americans every year ). Electrification of heating (solar-powered heat pumps are already economic in the northern US and Canada ) and can replace much of our natural gas use. Finally, electrification of transportation can be accomplished with electric vehicles, which are also already economic. Interestingly, in all of these, cases we are manufacturing constrained for photovoltaics, heat pumps and EVs (particularly batteries). We have also witnessed 3D printing reducing manufacturing time, fabricating superior products, and saving costs. There is already some evidence of this in these fields (e.g. 3D printing low-cost solar racking). In the future, I think we can expect to see 3D printed PV, heat exchangers in heat pumps, and electric batteries to help us kick the fossil fuel addiction.

![]() Dr. Ingo Ederer, CEO, voxeljet

Dr. Ingo Ederer, CEO, voxeljet