Launcher Unveils Orbiter – Its Universal Orbital Transfer Vehicle and Satellite Platform

June 15 2021, Launcher announced Orbiter, its universal orbital transfer vehicle and satellite platform designed to be compatible with both Launcher Light and SpaceX Falcon 9 rideshare flights. Orbiter is interoperable with either launch vehicle via a common 24-inch ESPA Grande adapter ring and is contracted to make its inaugural flight to sun-synchronous orbit via SpaceX Falcon 9 rideshare mission in October 2022.

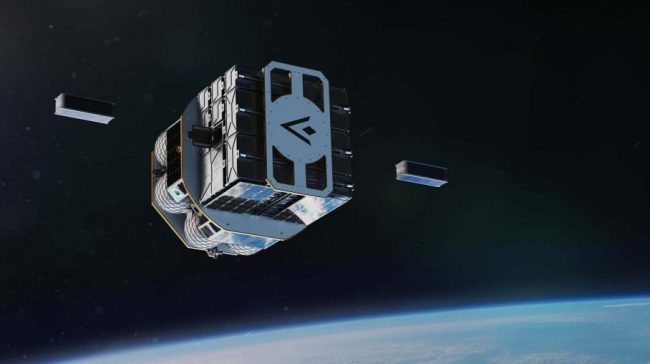

Illustration: Launcher Orbiter in modular CubeSat deployer configuration (90U available), deploying two 3U CubeSats. (Credit: Launcher)

Illustration: Launcher Orbiter in modular CubeSat deployer configuration (90U available), deploying two 3U CubeSats. (Credit: Launcher)

Orbiter can carry up to 150 kg of customer satellite payload in a modular stack of CubeSat deployers. It can also be configured to accommodate small satellite payloads directly on an integration surface compatible with small satellite separation systems. Orbiter is equipped with Launcher’s signature combination of high-performance, low-cost, high-thrust chemical propulsion that allows customers to customize their payload orbit according to their mission needs.

With Orbiter, small satellite constellation developers can take advantage of the rapid cadence and unprecedented price point of the SpaceX rideshare program to build their constellation at optimum cost and timing. To complete their constellation with additional orbits and schedules, customers can purchase a launch service using Orbiter for a dedicated ride to orbit on Launcher Light, Launcher’s own small orbital launch vehicle, slated for its first flight in 2024. Photo: SpaceX Falcon 9 (Credit: SpaceX)

Photo: SpaceX Falcon 9 (Credit: SpaceX)

“Orbiter delivers the best of both worlds: the ability to maximize and tailor launch opportunities for your constellation using SpaceX’s rideshare program, as well as the option to design additional complementary missions on a small, dedicated Launcher rocket when orbit requirements or schedules dictate,” said Launcher Founder and CEO Max Haot. “Customers benefit from working with the same partner, mission team, contract, qualification and regulatory processes, satellite interface, and orbital transfer vehicle hardware and software platform.”

Illustration: Launcher Orbiter encapsulated in the fairing of Launcher Light. (Credit: Launcher)

Illustration: Launcher Orbiter encapsulated in the fairing of Launcher Light. (Credit: Launcher)

Illustration: Launcher Orbiter shortly after being released from Launcher Light’s second stage. (Credit: Launcher)

Illustration: Launcher Orbiter shortly after being released from Launcher Light’s second stage. (Credit: Launcher)

Launcher designs and manufactures the majority of Orbiter’s components in-house to ensure competitive pricing for its customers.

Orbiter’s key capabilities:

- Hosted Payload Support with access to power, communication, attitude control, and propulsion, all while using Launcher’s secure browser-based ground control platform and API.

- Payload Interface capable of supporting up to 150kg of customer payload, including stackable and modular CubeSat dispensers and/or small satellite separation mechanisms. When in the CubeSat dispenser configuration, 3U/6U/12U dispenser combinations are available for up to an aggregate of 90U with industry-leading volume protrusion allowance.

- Precise Orbital Insertion – Full 3-axis attitude control through all phases post-launch vehicle separation. Available delta-V to change inclination, correct anomaly phasing, and shift RAAN. Tunable spring force on CubeSat deployers to achieve desired separation velocity.

- Command and Control – Manual and autonomous command and control via Launcher’s secure ground control platform integrated with commercially available global ground station networks.

- Payload Communication – High bitrate data communication for payload mission data.

- Video – High-resolution video cameras for vehicle monitoring, separations, deployments, or other key mission events.

- Avionics – Low-cost, Linux-based, reliable, in-house designed flight computer and software coupled with high flight heritage Commercial Off The Shelf (COTS) components.

- Power – Battery and solar arrays with power available for hosted payload use.

- Thermal Management – Hosted payloads have access to thermal control via onboard radiators.

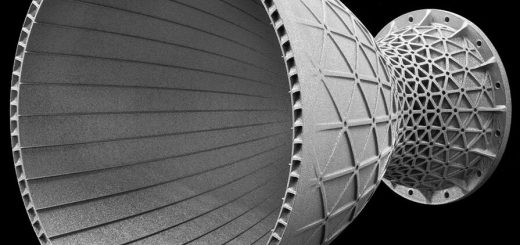

- Propulsion – Launcher-designed and -produced chemical propulsion module with low-cost, 3D printed propellant tank, combustion chamber, and injector. Propellants consist of Ethane and N2O for safe fueling and ease of ground operations. The first flight will feature approximately 500 m/s of delta-V capability to modify orbit as needed with transfer times measured in minutes, rather than weeks. Additional delta-V can be added through Launcher’s modular tank system.

- Failsafe Deployment – In the unlikely event of an Orbiter vehicle anomaly, a separate, autonomous, and fault-tolerant separation system activates to safely deploy all customer spacecraft.

- Launch Vehicle Interface – ESPA Grande 24’’ diameter separation system.

Illustration: Launcher Orbiter with propulsion module ignited. (Credit: Launcher)

Illustration: Launcher Orbiter with propulsion module ignited. (Credit: Launcher)

Typical mission capabilities:

- Sequenced and attitude-controlled spacecraft release with telemetry and video monitoring.

- 500+ m/s delta-V for required orbit correction.

- Controlled deorbit of Orbiter and non-separated payload upon mission completion.

- Ability to host Customer payload for extended-duration missions.

Orbiter is being designed as a long-term mission satellite platform from the ground up — supporting both short-term missions with precision payload release and long-duration missions with hosted payloads and access to high-speed payload communication, power, attitude control, thermal management, propulsion and a full ground control and communication service provided by Launcher.

Source: Launcher

For press release, welcome to send to 3D Science Valley at 2509957133@qq.com

Recent Comments