The New Bugatti Chiron Pur Sport Is Equipped with A 3D Printed Exhaust Tailpipe

The new Bugatti Chiron Pur Sport is equipped with a 3D printed exhaust tailpipe manufactured by APWORKS!

Image via APWORKS

Image via APWORKS

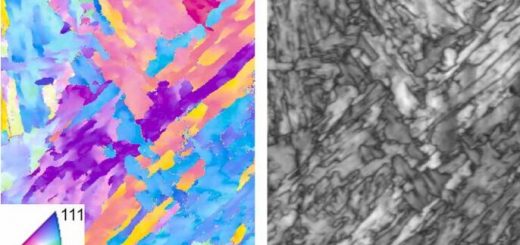

The sophisticated exhaust tailpipe applied in the Bugatti Chiron Pure Sport is additively manufactured out of Titanium at APWORKS. AM as a production method gives the component very thin walls, thus helping to save weight where it really matters.

Additive Manufacturing is the best suited manufacturing method for this application as it enables a degree of design freedom no other manufacturing method is capable of. The exhaust tailpipe is part of the extraordinary rear design of the Chiron Pur Sport – a new aerodynamic configuration that generates more downforce while the lower weight increases agility. “By cutting the weight by 50 kilogrammes while simultaneously boosting the downforce and configuring an uncompromising, sporty chassis as well as suspension setup, the Chiron Pur Sport boasts incredible grip, sensational acceleration and extraordinarily accurate handling. It’s the most uncompromising yet agile Bugatti of recent times.” explains Stephan Winkelmann, President of Bugatti. The low mass of the tailpipe contributes to the new aerodynamic configuration of the hypersports car dedicated for driving on extremely winding roads. This new Chiron is geared even more towards agility and dynamic cornering.

Image via APWORKS

Image via APWORKS

“We are proud to be part of this impressive new sports car development of Bugatti. It is the first visible metal 3D printed part receiving the road homologation. We could only realize this innovative tailpipe by pushing the additive manufacturing technology to the limit. Smallest wall thickness of below 0.5mm enable the extremely lightweight design.” says Joachim Zettler Managing Director of APWORKS.

The exhaust tailpipe is additionally highly temperature resistant due to the production out of titanium, as this material combines high strength and good heat resistance. This is a prime example of an optimized high-performance part enabled by additive manufacturing fulfilling highest quality standards an receiving the road homologation.

Source: APWORKS

Recent Comments