Loramendi, Voxeljet, Ask Chemicals – Industrialization of Core Printing (ICP): Official Introduction at GIFA 2019

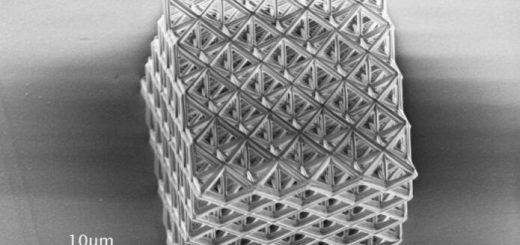

Loramendi, voxeljet and ASK Chemicals have taken a major step to reinvent the manufacturing landscape by developing the world’s first fully automated 3D printed core production solution. The technology called Industrialization of Core Printing (ICP) allows automated production of highly complex sand cores for casting processes. By harnessing the flexibility of additive manufacturing, ICP eliminates design limitations of conventional tooling and is capable of matching conventional core making in serial-production.

Loramendi&Aurrenak hold an extensive background as a leading group for the design and supply of complete solutions and turnkey projects for core making, moulding and casting services. With this broad expertise, Loramendi designed a fully automated, 3D printed, inorganic core production line. The ICP technology and equipment has been developed to enable a high production flexibility and to boost the opportunities of industry 4.0 for core making factories and foundries. The know-how and experience of Loramendi as a main contractor have been a key success factor to deploy this disruptive innovation by integrating process development and the equipment industrialization.

![]() Experience from traditional manufacturing empowers 3D Printing

Experience from traditional manufacturing empowers 3D Printing

“Loramendi has built equipment for the foundry industry for more than 45 years and nowadays enjoys world-wide prestige. We are recognized as a builder of heavy duty, reliable machinery and solutions specifically designed for the unique challenges of the foundry industry” stated JosebaGoitia, General Manager of Loramendi. “We are really excited about starting this new journey that will completely transform the landscape of the foundry industry and set new standards for core making.”

The new solution leverages voxeljet’s decades of research and expertise in precision mechanics, microfluidics and materials sciences and features a new type of 3D printer, which is more than ten times faster than previous models.

![]() 3D Printing industry reached the inflection point

3D Printing industry reached the inflection point

Dr. Ingo Ederer, Chief Executive Officer of voxeljet, commented: “We started nearly 20 years ago as a spin-off from Technical University Munich with a clear vision in mind: to match conventional manufacturing by constantly pushing technological boundaries. Today I can say that, together with our partners, we are set to become the world’s first to use fully automated 3D printing in automotive serial-production. The 3D printing industry is at an inflection point and this achievement marks a key milestone in our mission.”

Ask Chemicals, a leading supplier of innovative casting materials, developed the new inorganic binding materials and tailored them to the specific ICP requirements in order to meet the expected quality and productivity goals.

![]() Inorganic binder systems for 3D Printing unite sustainability and technological impact

Inorganic binder systems for 3D Printing unite sustainability and technological impact

“3D sand printing has been used in the foundry industry for many years to produce prototypes and small series. However, with the development of ever faster printers, the technology now offers new opportunities for foundries. We are therefore very pleased to take the important step towards industrialized core printing with our alliance partners Loramendi and voxeljet.”, states Frank Coenen, CEO of ASK Chemicals. The inorganic two-component system INOTEC 3D, consisting of an INOTEC 3D printing fluid and an INOTEC 3D promoter, is applicable for hot-curing additive manufacturing processes. Further advantages are the low finishing effort of the sand cores produced, which lead to castings of high dimensional accuracy and surface quality due to the high thermal stability. Above all, INOTEC 3D supports current trends in the engine casting segment of the light metal casting industry.

Source: voxeljet

Recent Comments