First Ever Fully Functional 3D Printed IoT Communication Device Developed for Use in Smart Homes and Products

Nano Dimension can now shorten development times for IoT devices by up to 90% compared with traditional devices

Nano Dimension Ltd., a leading additive electronics provider (NASDAQ, TASE: NNDM), announced today that it has created the first fully functional, 3D printed communication device, at a faster speed than has ever been achieved to date with traditionally made devices. This first ever additively manufactured (3D printed) IoT device developed by Nano Dimension, enables companies and research institutions to create and test their ‘smart’ products and other prototypes faster and more easily than ever before.

Nano Dimension completed the print, assembly and testing of the prototype IoT transceiver device in approximately 18 hours, which is about 90% faster than traditional (non 3D printed) devices which typically take approximately 14 days or more. The device was additively manufactured using Nano Dimension’s award winning DragonFly Pro 3D Printer – the only precision additive manufacturing system of its type worldwide.

Transceiver 3D printed with the DragonFly Pro system by Nano Dimension

The remote-control type IoT device, smaller than a silver dollar coin (16 x 33 x 1.6mm), is currently in its qualification phase and Nano Dimensions’ experts anticipate that it can easily and efficiently be developed into a two-way communication device (transmitter and receiver) such as a router.

Organizations who specialize in smart home routers may be able to assist organizations to speedily develop enhanced communication with smart white goods such as washing machines, refrigerators, televisions, air conditioning system, and even children’s toys. For example, smart TVs that can communicate with their owners reminding them that their favorite program is about to begin, smart fridges that can communicate that they are out of milk and children’s toys that can demand to be played with.

Furthermore, this device (essentially a printed circuit board) has much farther-reaching applications than just smart homes. Enterprises that manufacture autonomous vehicles, with their many hundreds of sensors, may be able to utilize this smart device developed with the help of the DragonFly Pro.

As more products become ‘smart’, eventually there will be no limit to the number of items that this seemingly simple device can connect to.

Amit Dror, CEO of Nano Dimension, said: “An ever-greater emphasis is being placed on smart cities, smart buildings, smart homes and smart products by industries and consumers alike. Our solution enables companies to speedily trial and finalize their prototypes in just one day without compromising on quality or performance. They no longer have to wait over a fortnight to understand whether their smart device works or not. This ultimately increases product and cost efficiencies and reduces time to market, which means that the consumer can enjoy the benefits of these products faster than ever before.”

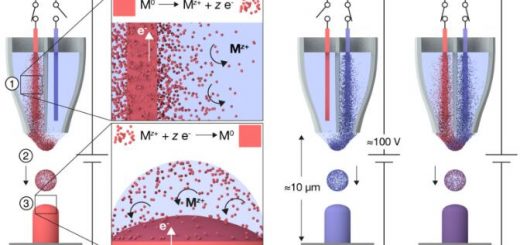

The only 3D printing system of its type worldwide, the DragonFly Pro 3D Printer, in some cases miniaturizes electronics making devices and circuit boards more efficient in capacity as well as in performance. It also boasts many applications including the Transceiver Application (transmitter and communicator) as described above, the Multilayer PCB Torque Sensor Application for creation of sensors required in almost every device, from a finger sensor in the average smartphone, to temperature and motion sensors in monitoring equipment, and the RF Amplifier Application which can massively amplify signals for portable communication devices and unmanned airborne vehicles such as drones and satellites, amongst many others.

The DragonFly Pro 3D Printer is poised to revolutionize the industry for electrical engineers as they know it, bringing with it huge and positive design implications.

Source: Nano Dimension

Recent Comments